Automated Surface Defect and Feature Inspection

Vastly improve inspection throughput and quality in aviation, aerospace, and other applications.

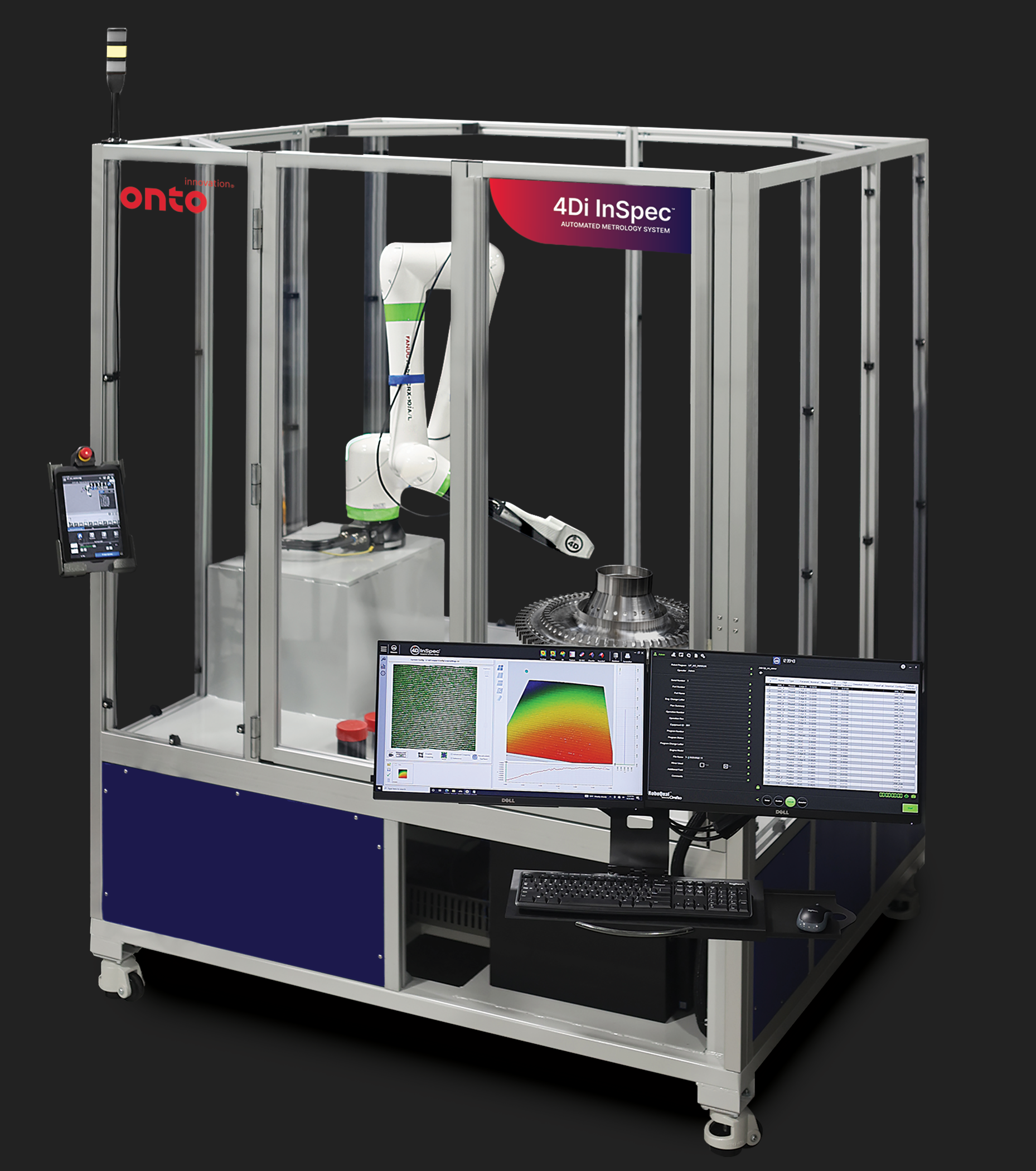

The 4Di InSpec automated measurement system (AMS) is a high-throughput, high resolution defect and feature inspection solution. The automated system can measure dozens of edge break features, chamfers, and radii in minutes rather than days, vastly improving throughput and driving down inspection costs.

Maximize process yield and quality

4Di InSpec AMS systems combine a non-contact 4D InSpec or 4D InSpec XL surface gage with a collaborative robot and other automation for rapid production inspection.

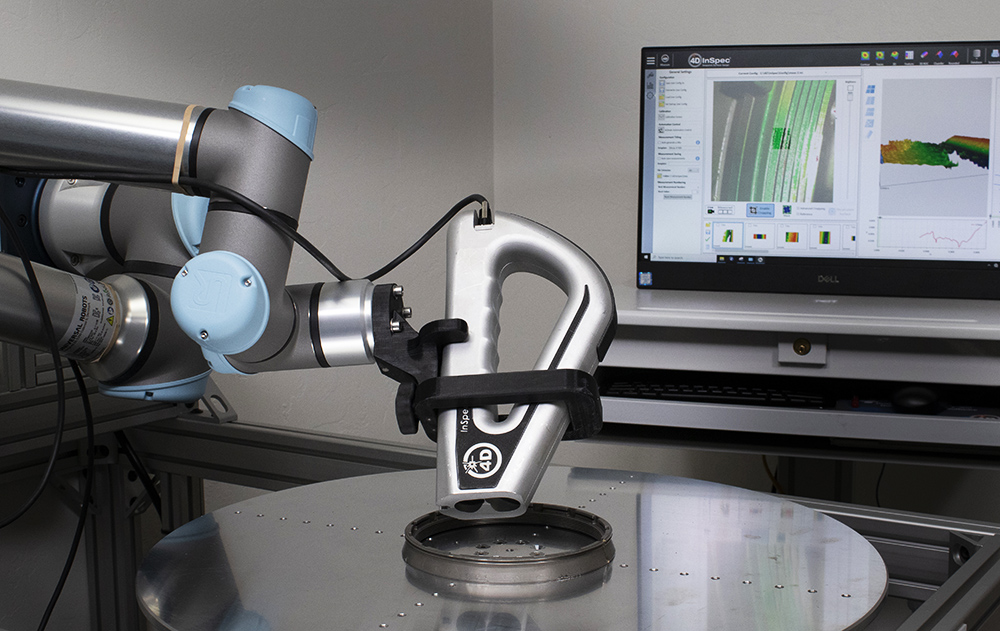

4D InSpec is the first precision instrument for non-contact surface defect measurement. Micrometer-level resolution, measurement in seconds, and immunity to vibration make it the tool of choice for high-resolution, 3D surface measurement in manufacturing, MRO, and field service applications.

Rapid Measurement—anywhere on a part

4Di InSpec AMS systems are the turnkey option for quality control of aerospace components such as turbine blades and rotors, air foils, high pressure compressor blades, blisks, and dovetails. The high resolution gage measures in any orientation, on curved surfaces, over large and complex geometries, and in tight spaces or blind locations.

Optional fold mirrors enable the gage to measure the insides of shafts, between gear teeth and fir tree roots, and in other tight spaces.

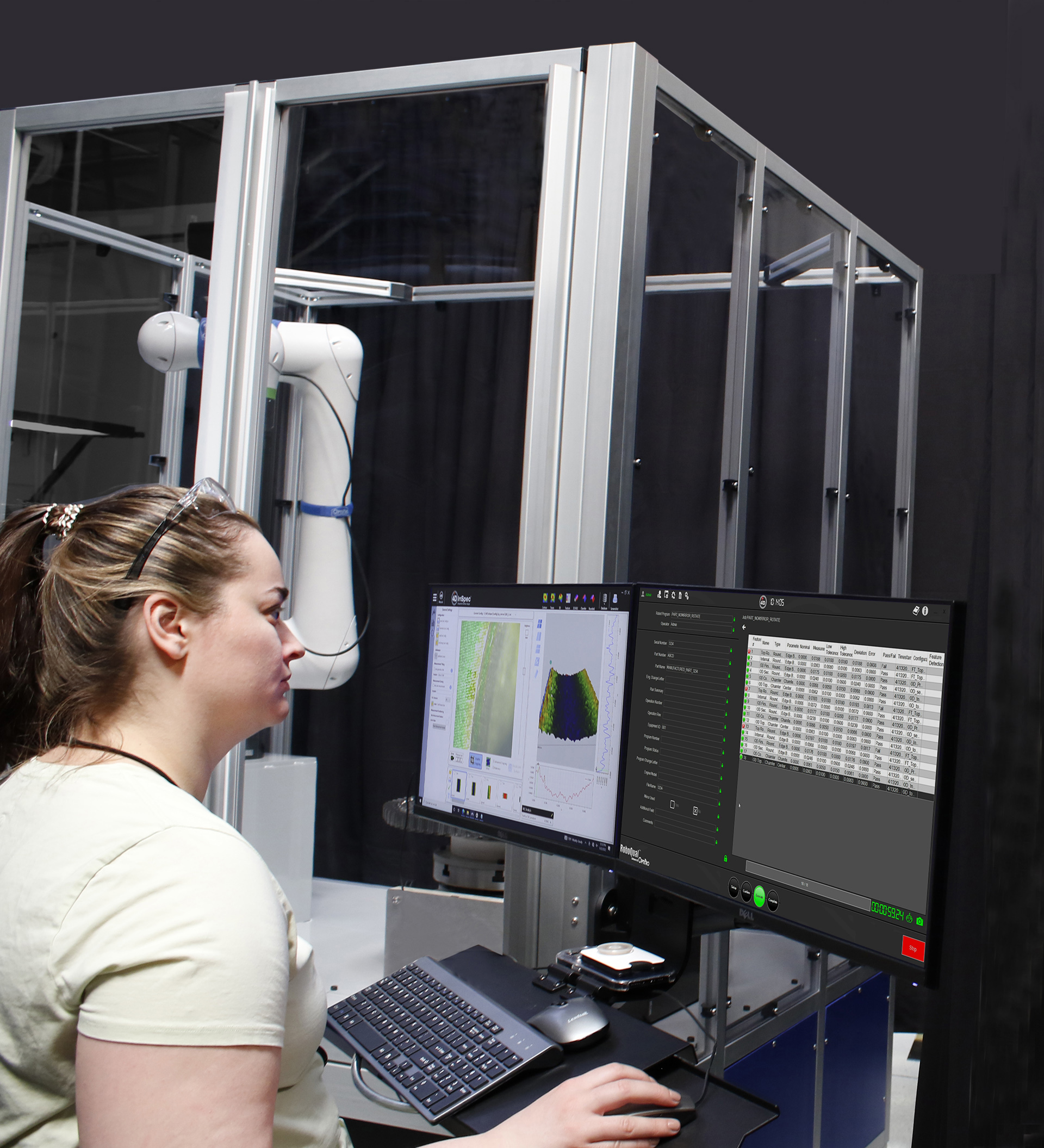

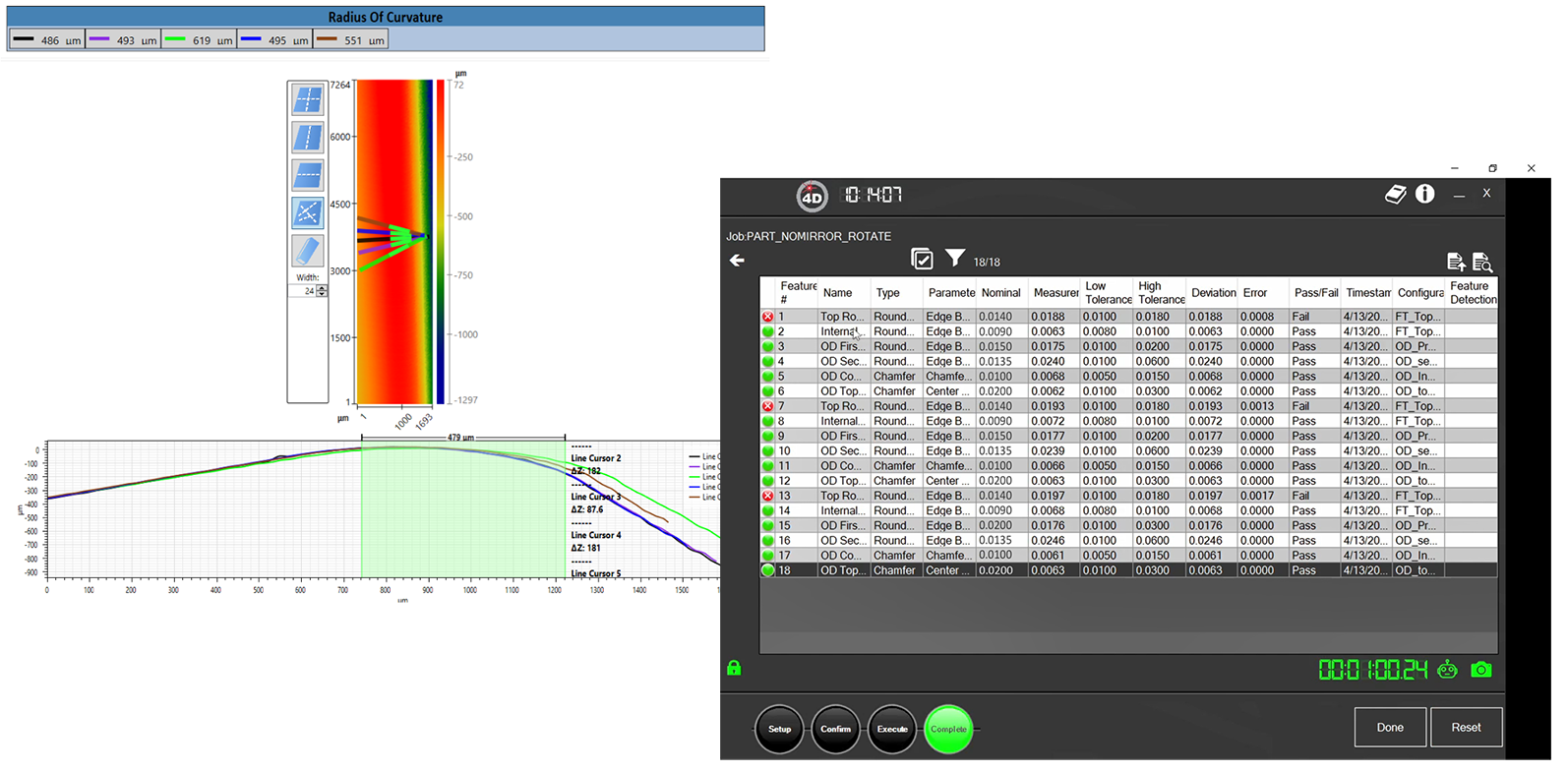

The 4Di InSpec AMS instantly produces high resolution, 3D measurement results, with far more information than other methods. An inspector can immediately see both an image of the feature and easy-to-read statistics. User-friendly measurement automation software flags any out-of-spec measurements and automatically remeasures the locations.

Choose the model

4Di InSpec AMS

-

- For Aero, aviation, and automotive development and production

- Universal Robotics UR-5 or UR-7 robot

- InSpec or InSpec XL sensor

- Optional rotary table

4Di InSpec AMS Cell

-

- For aviation and automotive manufacturing

- Inline design

- Fanuc CRX 5iA or CRX 10iA/L collaborative robot

- InSpec or InSpec XL gage

- Optional rotary table

- Mount gage or workpiece on robot

- Measurement automation software

- Safety cell

Innovative software

4di InSpec AMS systems include 4D InSpec software for acquiring and analyzing data. Automatic feature finding, 2D traces and 3D plots make it easy to analyze chamfers, edge blend, radii, and more.

Measurement automation software enables automatic re-measurement at failed locations.

Capabilities

Feature Analysis

Pass/Fail Analysis

-

Programmable pass fail/limits

-

Flag in- or out-of-spec

- Automatic re-measure of out-of-spec locations

Measurement Database

-

Save critical parameters to database

-

Save every measurement

-

Send data to SPC systems

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed