Industry standard for precision and innovation: vibration-insensitive 3D measurement

4D Technology is the leader in high-resolution surface, geometry and wavefront measurements for challenging locations and applications.

Discover our Products & Solutions

Optical Metrology

Astronomy, Optics Manufacturing, Aerospace & Defense, Free-space Optics & Research

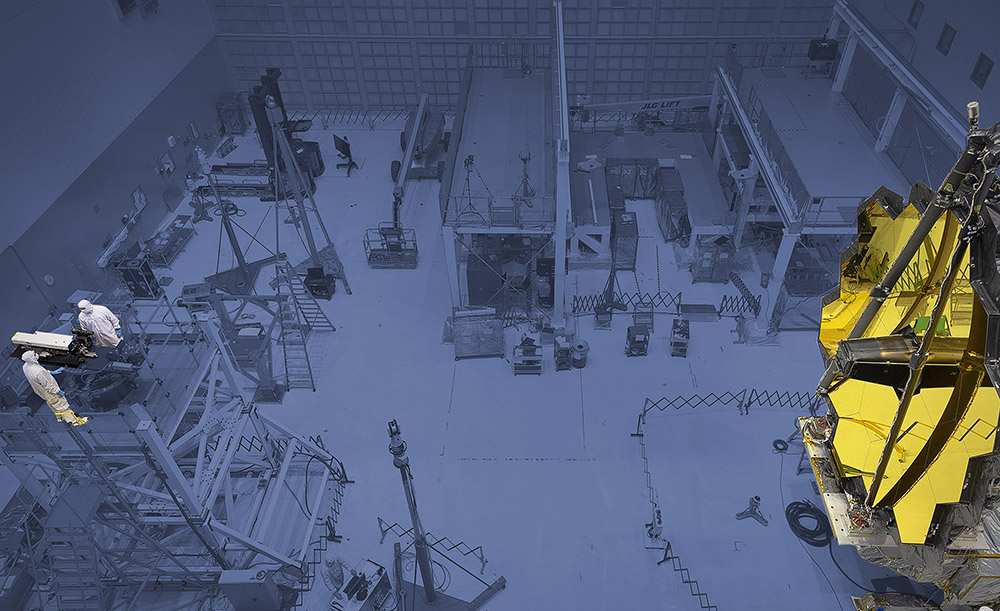

4D Technology’s Optical Metrology Products assure the quality of precision optics and optical systems. Our Dynamic Interferometry assures the surface and wavefront quality, despite vibration or turbulence.

It’s no surprise that virtually every space- and ground-based telescope for the last two decades has been tested with 4D instruments.

Across the spectrum, from UV to LWIR, 4D instruments, technology and software are everywhere optics are made and used.

Industrial Inspection

Aerospace, Aviation, MRO, Precision Machining, Medical Devices, Renewable Energy & Automotive

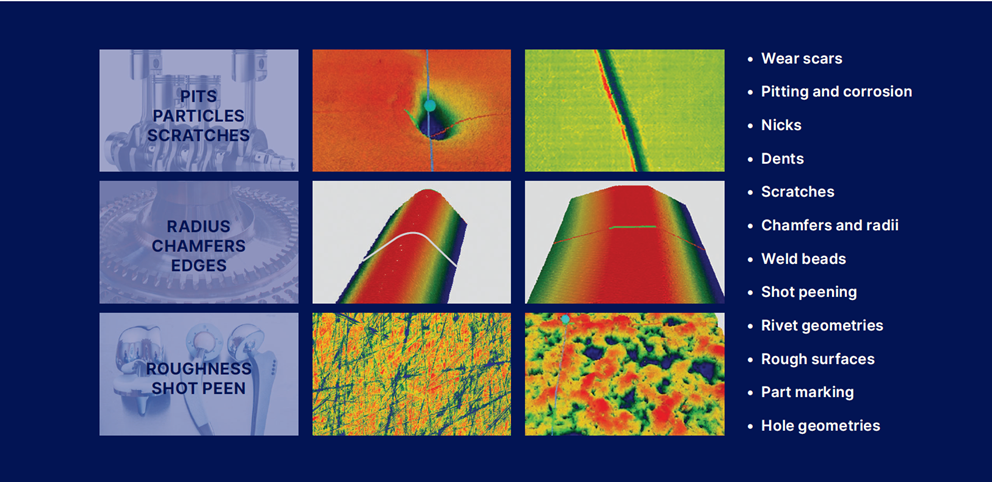

High-resolution, optical 3D measurement gauges you can bring right to your part. With one-button operation, quickly and accurately quantify defects such as pits, scratches, and corrosion and geometries such as edge break, chamfers, and radius.

Handheld, shop floor, and automated capabilities.

Measurement anywhere.

PhaseCam Twyman Green

- Twyman-Green interferometer

- Patented instantaneous, vibration-immune technology

- Concave optics, meter-class telescope optics, large imaging system alignment, moving parts

- VISIBLE-NIR-SWIR-LWIR

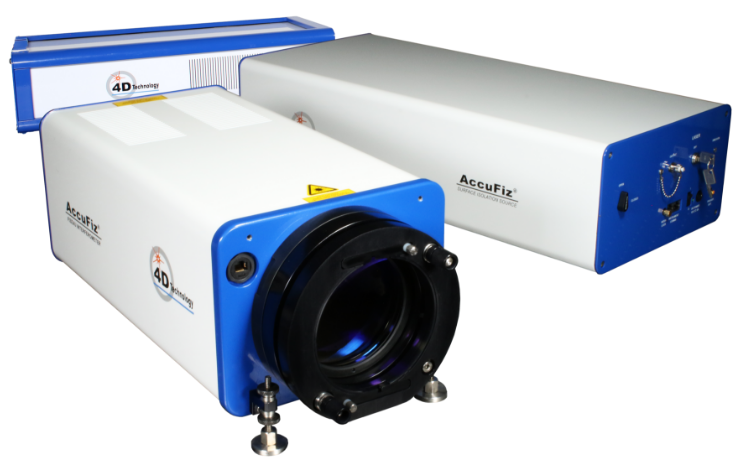

AccuFiz Fizeau

- Fizeau interferometer with dynamic interferometry

- Flats, lenses, vacuum/environmental chambers

- VISIBLE-NIR-SWIR

NanoCam Optical Profiler

- Patented instantaneous, vibration-immune surface roughness profiler

- Optical polish and surface finish

- Angstrom-level resolution

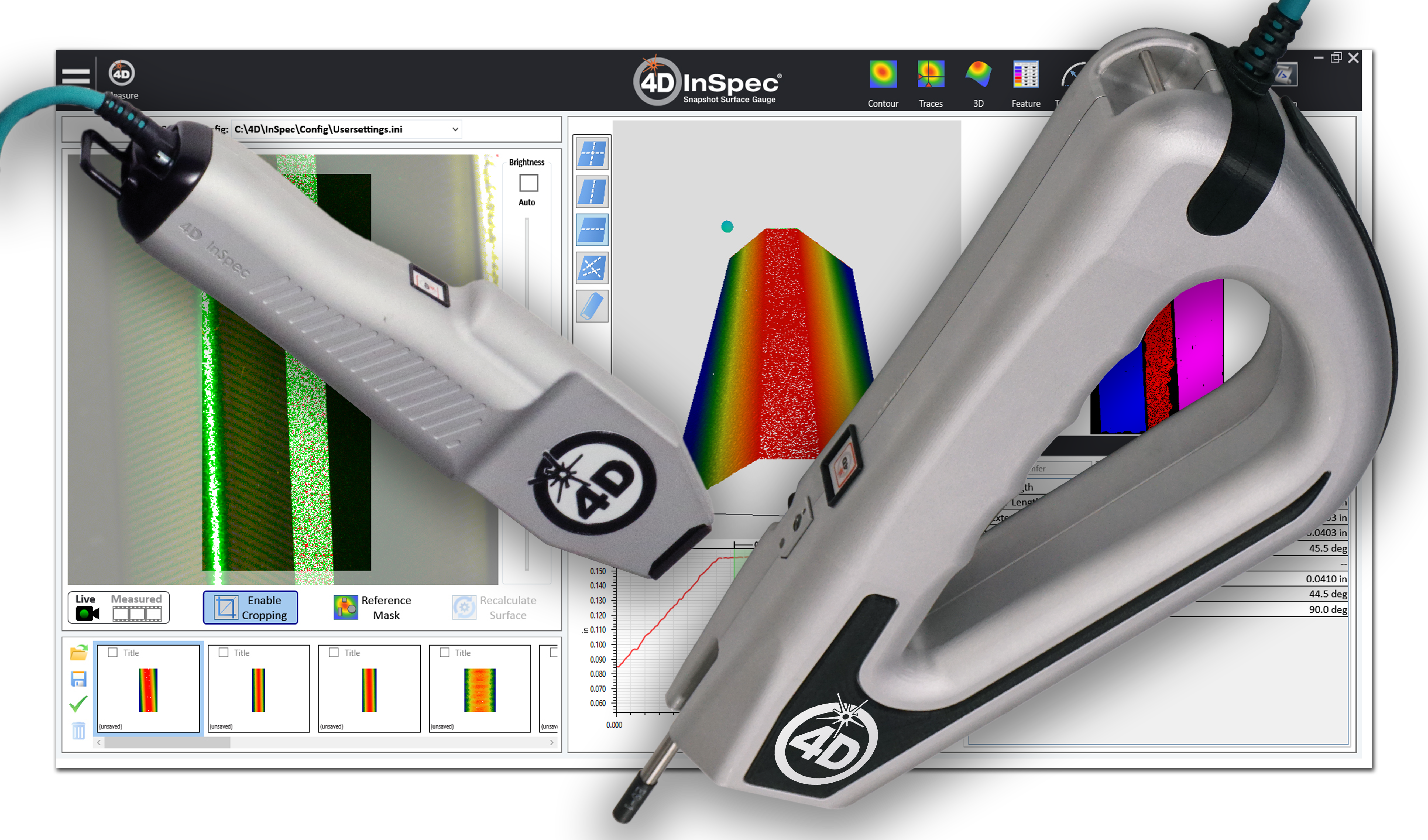

4D InSpec Optical Surface Gauge

- Patented instantaneous 3D surface measurement

- Portable, shop floor measurements

- Measure features such as edge break, chamfers, and radii and defects such as pits, dents, and corrosion

- Measure down to 2 microns

- Handheld, workstation, or robot-mounted

4Di InSpec AMS

- Automated surface defect and feature inspection

- High-throughput, high-resolution

- Measure dozens of features and defects in minutes rather than days

4D SurfSpec Coating Gauge

- Coating assurance gauge

- < 15nm resolution

- Raw materials, e-coat, & painted surfaces

- Portable handheld or robot-mounted

References for Optical Testing

Why Choose 4D?

What’s New

Webinar: Meeting Next-generation Optical Component & System Metrology Needs

In this webinar hosted by Photonics Spectra, Dr. Erik Novak, Vice President, 4D Technology, talks about how the demand for precise, reliable metrology is growing as optical systems evolve toward greater design complexity. It also highlights how vibration-insensitive...

Onto Innovation’s 4Di InSpecTM SR Surface Roughness Gauge Wins the International SPIE 2026 Prism Award in the Test and Measurement Category

Portable, vibration-immune, 3D surface roughness system transforms precision inspection by bringing the metrology directly to the part – right on the shop floor.Onto Innovation Inc. (NYSE: ONTO) is proud to announce that its 4Di InSpecTM SR Surface Roughness Gauge...

Advancing Surface Metrology Through Portable 3D Optical Inspection

In this interview conducted by AZO Optics, Jenna Perryman, Product Manager for the 4Di InSpec product line, discusses how vibration-immune optical metrology is transforming on-site surface defect and roughness measurement. She explains how the technology enables...

Optical 3D Defect and Roughness Inspection – Right on the Shop Floor

Achieve precise, high-resolution measurement of defects, surface features, and roughness—right where you work 4D Technology’s handheld optical gauges are engineered to be vibration-insensitive, enabling ultra-fast 3D surface measurements in less than 10...