Surface roughness

Measuring surface roughness and surface texture of machined components provides critical data that can be used to control and improve performance. Functionality ranging from appearance to adhesion to fit all benefit from a thorough understanding of the 3D surface texture of critical surfaces. Roughness measurement also aids maintenance personnel. Measuring surface roughness over time helps to guarantee functionality as a component wears and may indicate ways that wear can be reduced or eliminated.

In the world of optics, measuring and controlling roughness on blanks and substrates leads to proper adhesion and finish during coating operations. The roughness of coated surfaces can also be measured to indicate the effectiveness of the coating and polishing operations and to verify the performance of the final article.

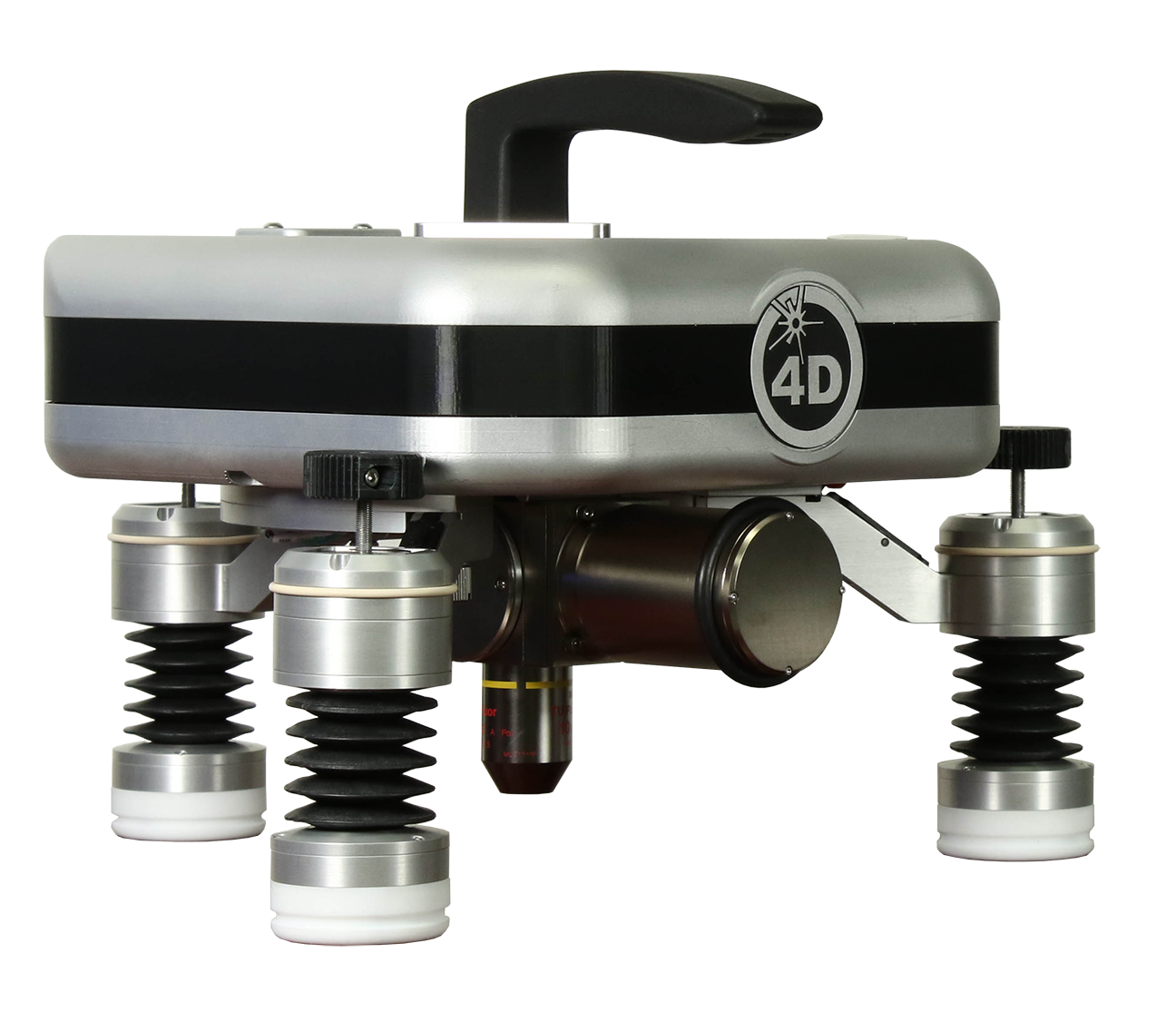

4D Optical Surface Profilers measure surface roughness in shop floor environments, without vibration isolation. The compact NanoCam HD measures smooth and super-smooth surfaces and can be used in situ in polishing equipment, on gantries or robots, or directly on large components.

Custom Solutions bring the power of roughness measure to roll-to-roll (R2R) manufacturing of flexible electronics, for real-time monitoring and control of roughness to less than 0.5 nm rms.

Measuring Sub-Angstrom Roughness

How do you measure roughness with sub-angstrom precision in a noisy manufacting environment?

Read this white paper for a break-down of the options, and illustrations of the challenges present in different solutions.

Added Technical Resources

Measuring MEMS and other vertical roughness surfaces

A new technique provides a faster, more repeatable method for vibration-insensitive measurement in non-ideal environments.

Measuring Surface Features with High Resolution in Factory Environments

This article from Industrial Photonics magazine illustrates how the ability to measure surface defects and features anywhere in the factory or on the flightline can be a transformative change in quality control procedures.

Products for Surface Roughness

Optical Profilers

NanoCam HD systems measure surface roughness on coated and uncoated precision surfaces to ensure the quality of polishing processes.

4D InSpec

4D InSpec provides non-contact measurement of surface features and defects, on the factory floor, in machine shops and in field service applications.

Do you need custom-built metrology?

Get a free consultation. 4D Technology’s mechanical, optical, electrical and software engineering teams are standing by to evaluate what it would take to meet your application’s requirements.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed