Surface Inspection Gauge for the shop floor

4D InSpec® increases yield 20-40% in machine shops and rework centers.

20%-40% improvements in yield are typical reported figures from 4D InSpec purchasers.

By measuring a part’s nominal defect features right up to the line of the specification, customers find that they are able to pass more parts, and rework many parts that a fingernail test, comparator, or pocket stylus would have failed.

Not sure which model is right for you?

Follow the link to learn more

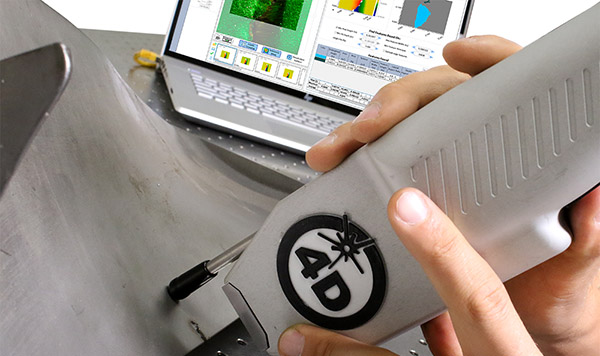

Handheld, instant 3D measurements

The 4D InSpec surface gauge is the first handheld, precision instrument for non-contact surface defect measurement. With micrometer-level resolution, portability, affordability and ease-of-use, 4D InSpec puts high resolution 3D surface measurement where it’s needed: on the factory floor, in machine shops, and in field service applications.

Even with this surface gauge being precise and capable of extensive analysis, it’s incredibly easy to use. Non-experts can take measurements with ease after just minutes of training.

4D InSpec instantly quantifies defects such as pits, scratches, nicks, dents and bumps. It measures features such as edge break, radii, rivet depth and dot peen depth up to 100 mils (2540 micrometers) deep. 4D InSpec is far more repeatable and accurate than visual comparison techniques typically used for surface defect measurements. And unlike high-end metrology systems, it is rugged, flexible and affordable, to measure a wide range of part geometries in the most challenging environments.

“They are able to measure around a curved surface, they are able to measure in a divot, or measure many different areas of the engine we were not able to measure before accurately, you could just not do it. There was nothing out there that could do it.”

hundreds of Units installed

MRO Engine Support

Using the 4D InSpec

The 4D InSpec can be handheld to access tight corners or to sample large surfaces directly on components. An optional fold mirror accessory lets the system function like a borescope to access sidewall features without line of sight. One-button operation and immunity to movement make it easy to align and measure, while a rugged design and single cable tether withstand the rigors of daily use.

4D InSpec makes it fast and easy to obtain repeatable quality control data. An intuitive, touchscreen interface handles setup, operation, analysis and report generation. The 4D InSpec can also be mounted on a robotic manipulator for fully automated measurements of complex components.

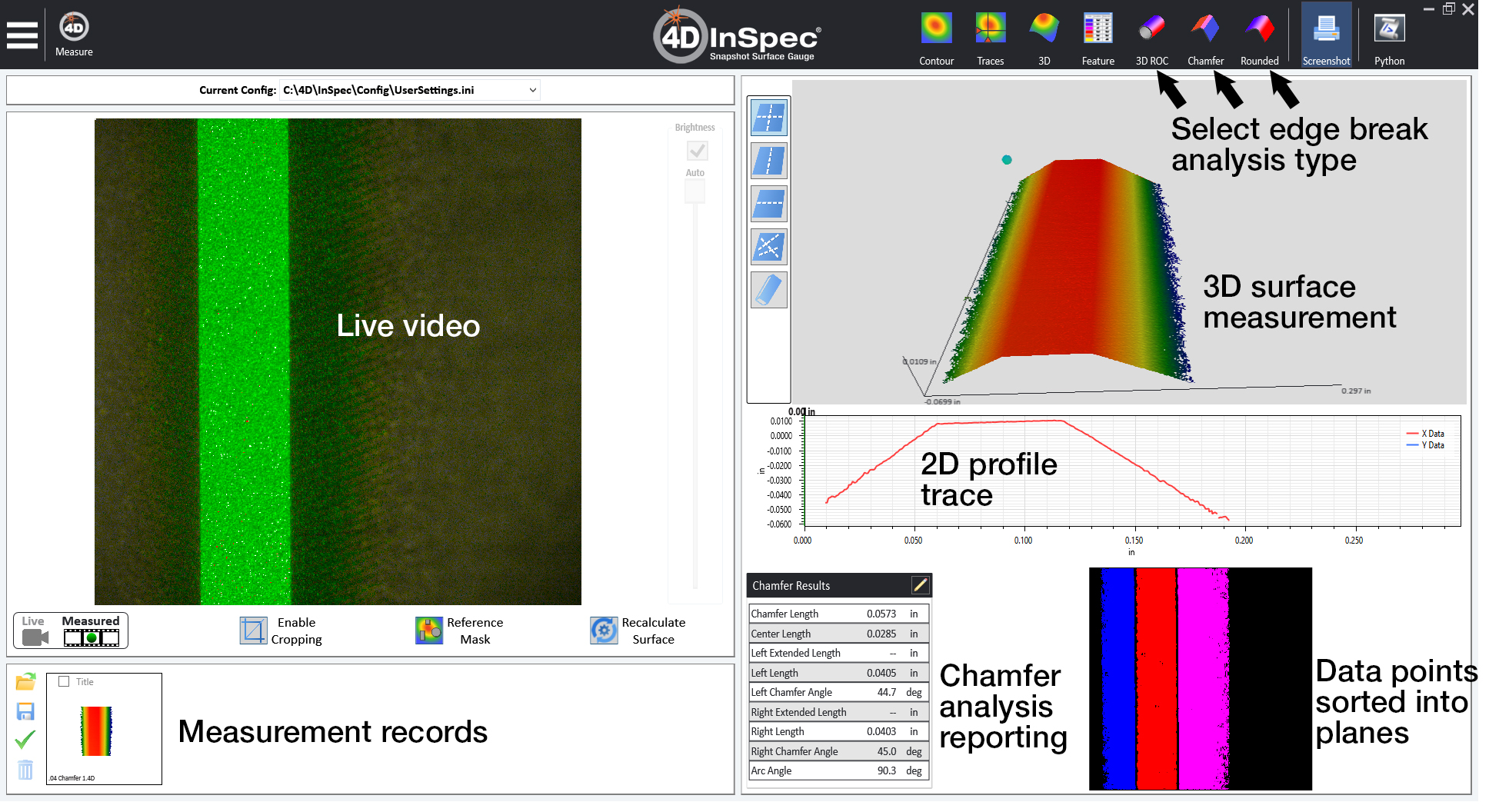

The included software automatically bins defects in the measurement area, and 3D feature analysis calculates their height, volume, area, slopes and location. Imagine measuring an area of corrosion pits and knowing how many of them are deeper than your spec, in a single button click. The operator can choose from 2D traces or 3D plots to view defects in greater detail. The system supports easy data transfer to quality control systems via LAN, USB or WiFi for rapid, networked, pass-fail analysis.

Available in two models

4D InSpec

-

-

Field of view (standard): 0.3 x 0.3 in (7.7 x 7.7 mm)

-

Vertical resolution: 0.00008 in (2.0 µm)

-

Depth of focus: > 0.10 in (2.5 mm)

-

4D InSpec XL

-

-

Field of view (XL): 0.6 x 0.6 in (15 x 15 mm)

-

Vertical resolution: 0.00027 in (7 µm)

-

Depth of focus: > 0.35 in (9 mm)

-

Learn about the 4Di InSpec AT

for automated feature and defect measurement

Innovative software

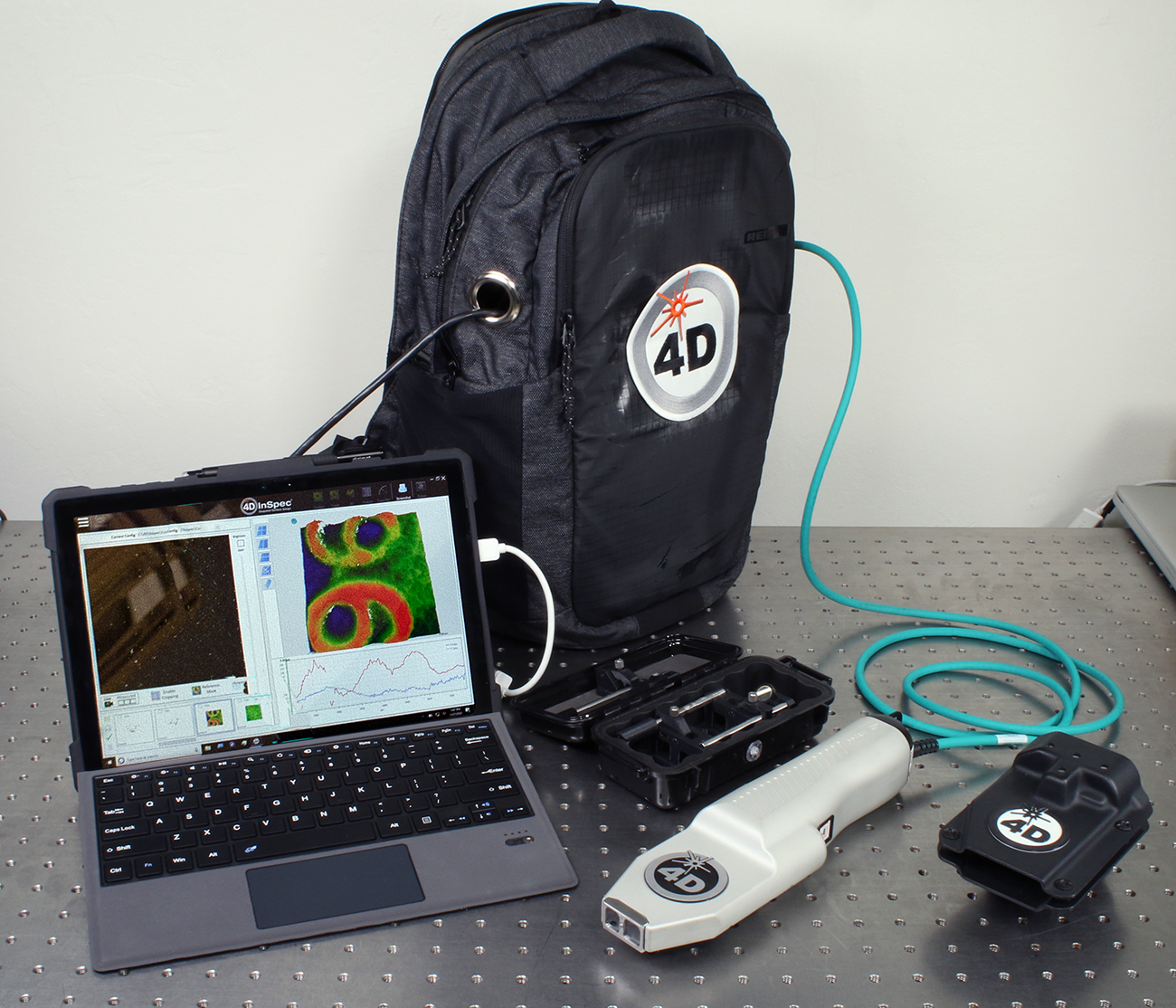

A complete 4D InSpec system includes the instrument, computer with HD 1080p touch-screen interface, single Ethernet cable tether, software, and benchtop stand. A full selection of accessories, including a portable workstation, and Li-ion rechargeable battery with up to 8 hours operational time, are also available to improve portability and productivity.

Highlighted capabilites

Feature analysis

Pass/Fail flagging

-

Feature analysis

-

Set pass/fail spec

-

Flags in- or out-of-spec

Measurement database

-

Save critical parameters to database

-

Save every measurement

-

See trends

-

Retain history

Optional edge break

-

Measure chamfer rounding and radius of curvature

-

Independent of skew and tilt

-

Repeatable and accurate

-

One second to measure

Accessories

Shopfloor cart

Backpack Trekker kit

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed