Homogeneity

When an optic is used in transmission, any variations in the material’s index of refraction will translate to errors in the wavefront passing through the optic. It is therefore important for manufacturers to be able to measure the homogeneity of the index, both in bulk materials samples and in completed optics.

In transmission, however, error is also introduced through imperfections in the shape of the sample’s front and back surfaces, as well as inhomogeneity. Isolating these error sources can be challenging, particularly when the front and back surfaces of the optic are close to parallel.

The measurement procedure with a traditional interferometer may require many hours and tedious alignment for each measurement step. The difficulties only increase for larger optics.

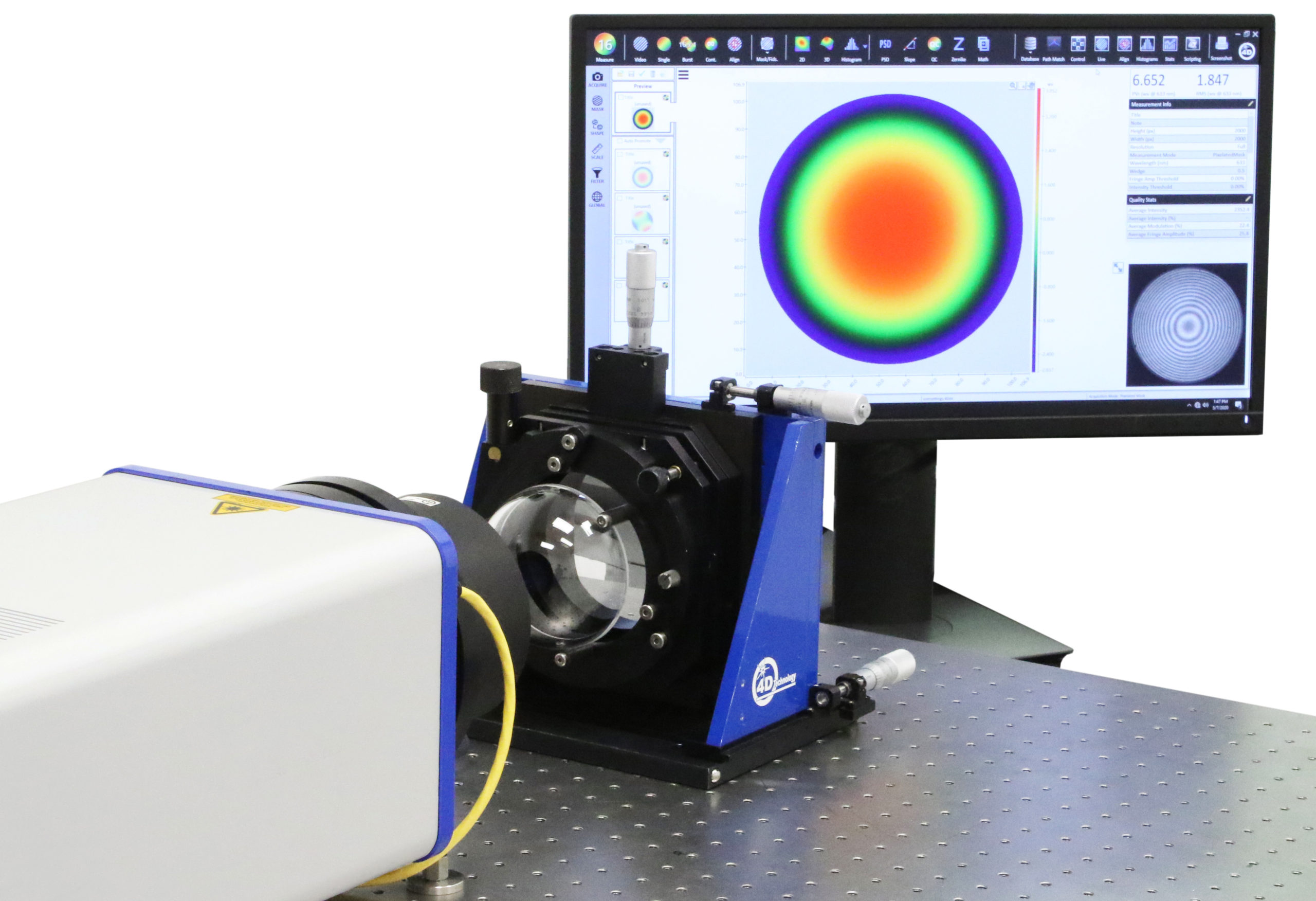

A homogeneity measurement made with the AccuFiz D.

AccuFiz D Simplifies Homogeneity Measurement

Several advances that are incorporated into the AccuFiz D Short Coherence Laser Intereferometer simplify homogeneity measurement to a procedure that involves only three measurements and a single test setup, with no realignment between steps.

Vibration-Immune Measurement

The AccuFiz D acquires all phase data simultaneously, resulting in extremely short integration times that make the system insensitive to vibration and air turbulence. Homogeneity can be accurately measured even without isolation.

Solid Cavity Measurements

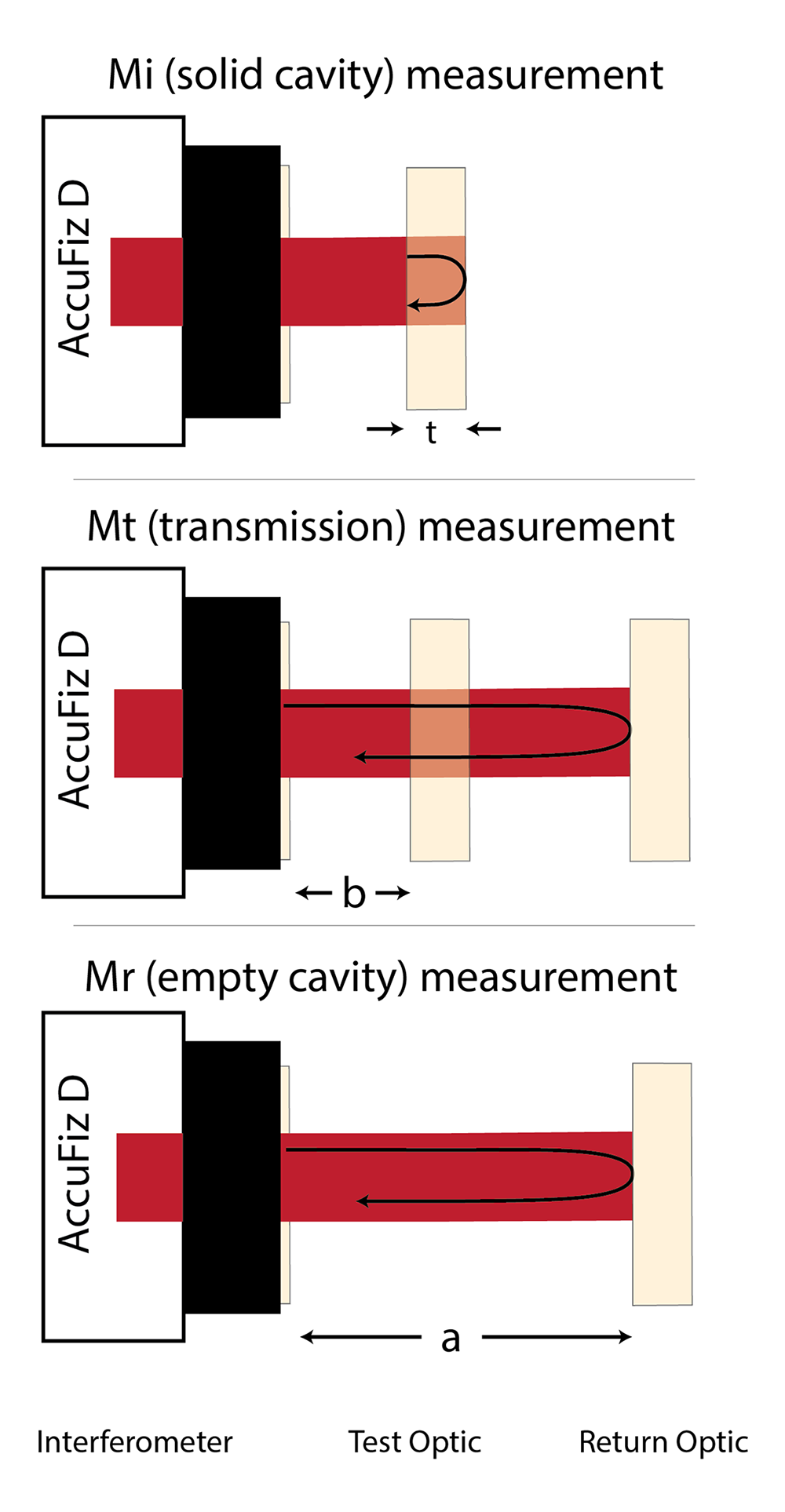

Unlike a traditional interferometer, the AccuFiz D does not require the reference surface to be translated relative to the test surface during measurement. It is therefore possible to measure the “solid cavity” of an optic, using the two surfaces of the optic as the test and reference. This measurement is not possible using a phase-shifting interferometer.

Isolating Reflections

The AccuFiz D has a short coherence (~300 μm) laser source that isolates the interference from any particular pair of reflections in the beam path. An internal “Path Matching” mechanism lets you select the pair of surfaces of interest, making it possible to isolate the error contributed by each surface and from the material itself.

Measuring homogeneity with the AccuFiz D is more accurate and far faster than with a traditional interferometer.

Improved Homogeneity Measurement

With the AccuFiz D the homogeneity of plane-parallel optics can be obtained from only three measurements, with a single test setup:

- solid cavity measurement

- empty cavity measurement

- the sample in transmission.

Since all measurements occur in a single setup, no alignment is required between measurements. This results in highly accurate homogeneity measurements—without the hours of alignment typically required to test with a traditional interferometer.

The AccuFiz D can also measure homogeneity in optics with more highly wedged surfaces. The procedure requires just four measurements, and, again, no alignment between steps.

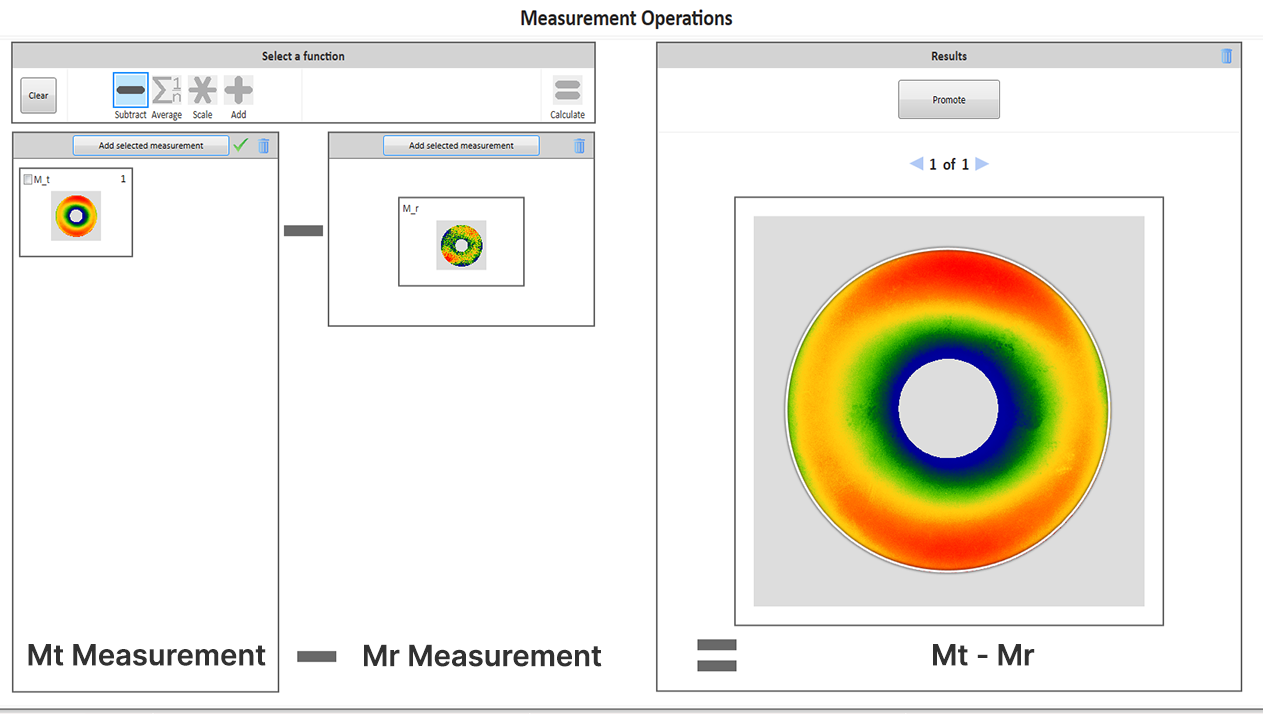

4Sight Focus software, included with the AccuFiz D, makes it easy to calculate homogeneity with step-by-step arithmetic functions.

4Sight Focus math operations make it easy to calculate homogeneity by dragging and dropping measurements.

Added Technical Resources

Measuring Homogeneity with the AccuFiz

A new technique simplifies measurement of homogeneity to decrease measurement time and improve repeatability.

Products for Homogeneity

AccuFiz SIS

AccuFiz with a Surface Isolation Source (SIS) uses short coherence to isolate the plane parallel optics, providing a capability to measure homogeneity with only three measurements.

AccuFiz D

High accuracy measurement of flat and curved transparent optics. Its short coherence length source means you can measure plane-parallel surfaces <0.2 mm apart without the need for coating to eliminate unwanted fringes.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed