Edge Break

The sharp edges of most precision machined surface are “broken” through a process called “edge break.” Edge break is accomplished by rounding off the corner, or by machining a flat “chamfer” to reduce the sharpness of the edge. The process is intended to ensure part longevity, safe handling, and proper performance.

Edge break serves several purposes depending on the application. Radiused and chamfered edges limit possible fracture points for components that are subject to high stresses or loads. Where component edges may effect air flow, such as turbine blades and nozzles, tight edge break tolerances ensure proper aerodynamic performance. Chamfers may also be added to fasteners to ensure that they do not protrude from shafts or casings. Lastly, in all of these cases, edge breaking reduces injuries from sharp edges and burrs, both in the production environment and in the field.

“Wow, in the 5 years of doing this I always thought I had a heavy hand. This is the first time I know a did the part to spec.”

Visual inspection cannot quantify edge break

Traditionally on the shop floor, edge break geometries have been inspected visually, often using an optical comparator. But visual testing, while fast and convenient, is inherently subjective. Judgments vary depending on the inspector, lighting, and alignment of the visual comparator. More importantly, a visual test provides no quantifiable data.

Single-trace methods are too variable for precision measurements

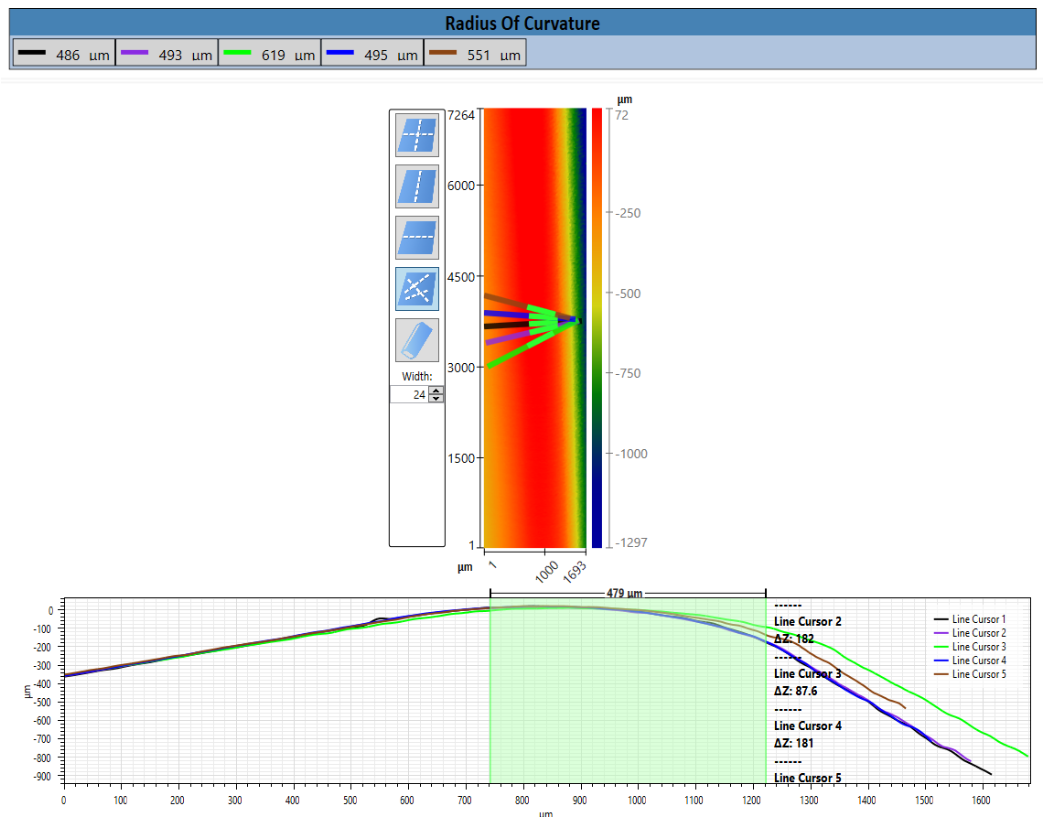

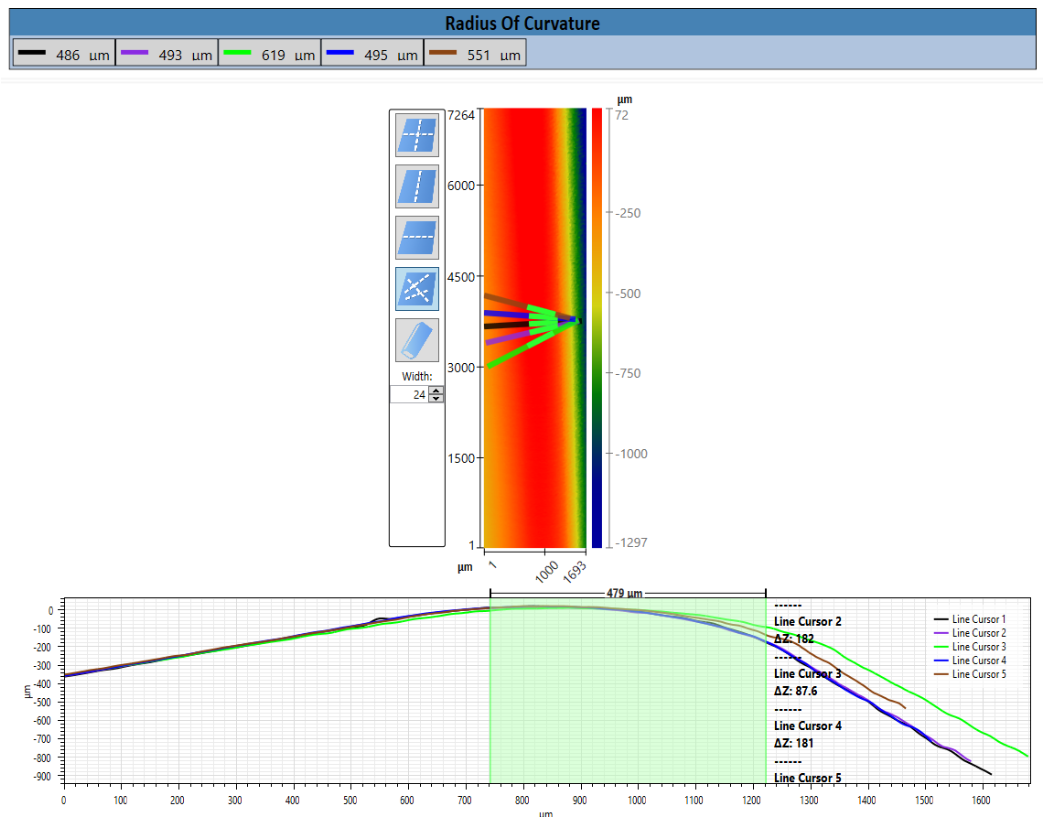

A 2D portable stylus profiler is a common instrument for quantifying edge break and chamfer geometries. Though widely used, single-trace measurements are prone to large errors due to variability in both the location and angle of the measurement, as the image below shows.

Stylus-based profilers can also struggle to measure over sharp edges without breaking the stylus tip. The stylus profiler’s limited vertical range may prevent it from being able to measure large chamfers on machined holes. Add in the technology’s susceptibility to vibration, and it’s clear how this “fast” method can often take more than 30 minutes of setup and scan time to achieve a single high-quality trace.

Other methods, such as laser-based gage guns, provide some shop-floor capability for edge break and chamfer measurements, but only over a single line. Alignment errors persist, and low resolution means they cannot measure fine geometries. Material finish, reflectivity and slope can also affect measurement results.

Related video: Measuring edge break and chamfer with a handheld gauge

3D measurement provides accurate, repeatable edge break analysis

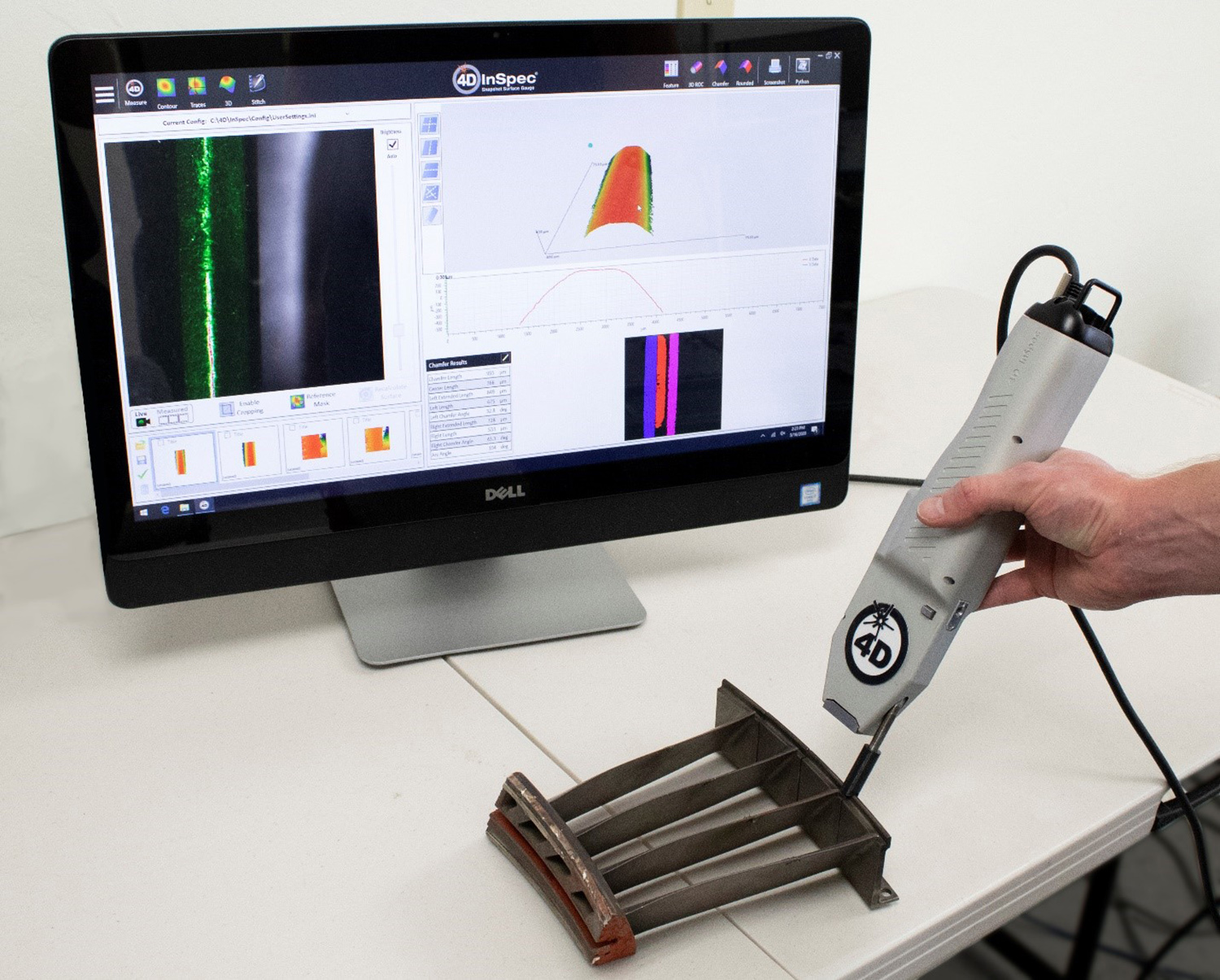

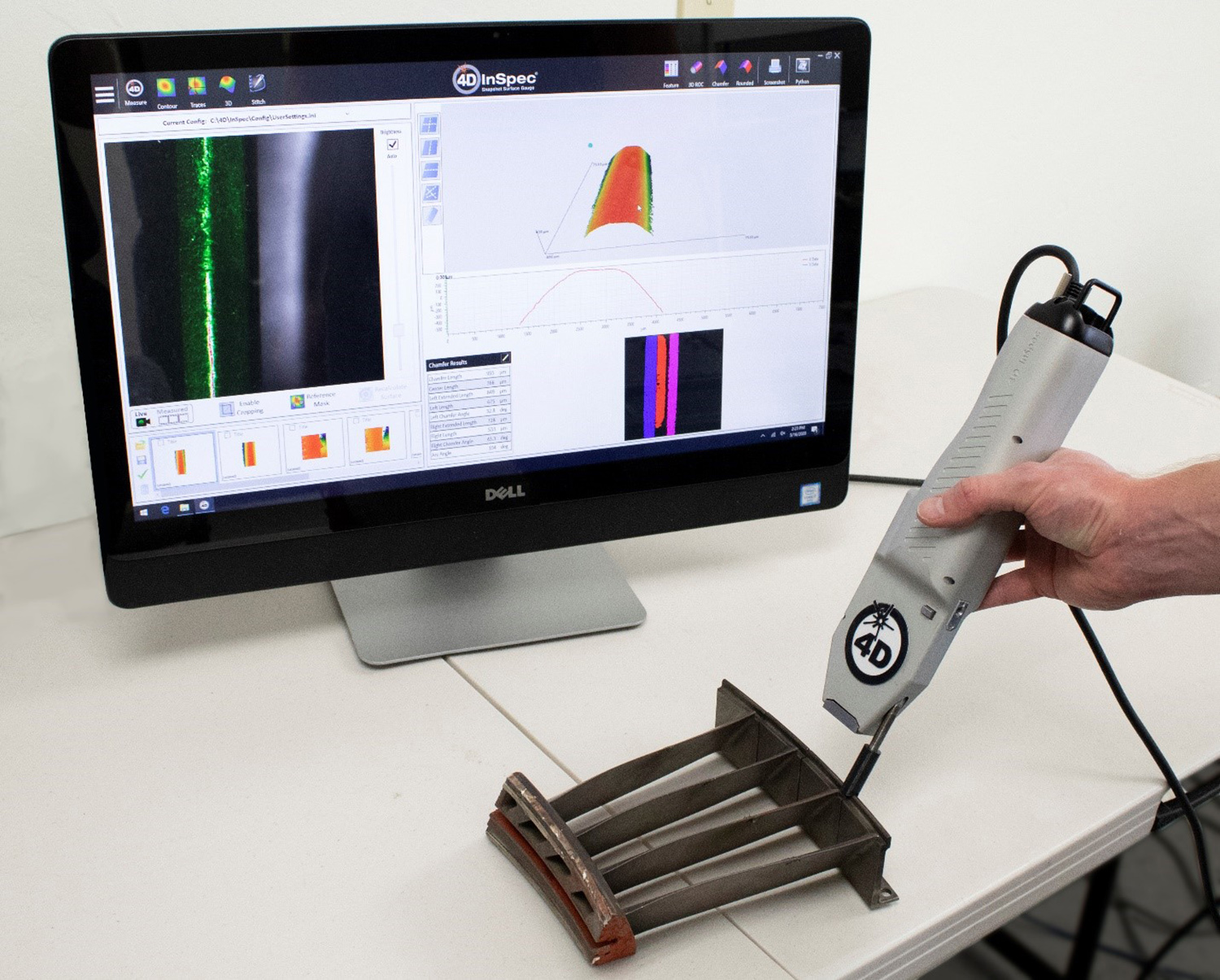

4D InSpec is a handheld, 3D measurement device that uses polarized structured light for rapid, simple, shop-floor measurement of edge break, chamfer angles, and other precision part geometries. Accuracy, repeatability, reproducibility, and durability make the 4D InSpec the right tool for measuring edge break in shop-floor environments.

The strength of this, you can see by picturing a measurement that behaves like the illustration below. By using planes connected in 3D to represent the chamfer and joining sides, the essential parameters become independent of orientation of the gauge–all profiles are calculated in respect to the direction of the planes.

How edge-break measurement works

The handheld 4D InSpec can be aimed directly at the edge to be measured. Alignment is trivial because it’s easy to get the correct distance, and angle variability is robust. The system provides immediate feedback to generate highly repeatable, 3D measurements of the entire edge—not just a single trace.

Having a 3D measurement alone is insufficient to analyze edge break, however. The software included with the 4D InSpec aligns plane and cylinder fits to the geometry, rather than treating the measurement as a series of adjacent traces. This method compensates for tilt and rotation of the instrument with respect to the multiple surfaces being measured.

Using this method, measurement results are based on the 3D plane and cylinder fits, rather than a single trace or even an average across multiple traces. This method greatly improves accuracy, records the results numerically, and makes for much more repeatable measurements.

Stylus-based profilers can also struggle to measure over sharp edges without breaking the stylus tip. The stylus profiler’s limited vertical range may prevent it from being able to measure large chamfers on machined holes. Add in the technology’s susceptibility to vibration, and it’s clear how this “fast” method can often take more than 30 minutes of setup and scan time to achieve a single high-quality trace.

Other methods, such as laser-based gage guns, provide some shop-floor capability for edge break and chamfer measurements, but only over a single line. Alignment errors persist, and low resolution means they cannot measure fine geometries. Material finish, reflectivity and slope can also affect measurement results.

Related video: Measuring edge break and chamfer with a handheld gauge

3D measurement provides accurate, repeatable edge break analysis

4D InSpec is a handheld, 3D measurement device that uses polarized structured light for rapid, simple, shop-floor measurement of edge break, chamfer angles, and other precision part geometries. Accuracy, repeatability, reproducibility, and durability make the 4D InSpec the right tool for measuring edge break in shop-floor environments.

The strength of this, you can see by picturing a measurement that behaves like the illustration below. By using planes connected in 3D to represent the chamfer and joining sides, the essential parameters become independent of orientation of the gauge–all profiles are calculated in respect to the direction of the planes.

How edge-break measurement works

The handheld 4D InSpec can be aimed directly at the edge to be measured. Alignment is trivial because it’s easy to get the correct distance, and angle variability is robust. The system provides immediate feedback to generate highly repeatable, 3D measurements of the entire edge—not just a single trace.

Having a 3D measurement alone is insufficient to analyze edge break, however. The software included with the 4D InSpec aligns plane and cylinder fits to the geometry, rather than treating the measurement as a series of adjacent traces. This method compensates for tilt and rotation of the instrument with respect to the multiple surfaces being measured.

Using this method, measurement results are based on the 3D plane and cylinder fits, rather than a single trace or even an average across multiple traces. This method greatly improves accuracy, records the results numerically, and makes for much more repeatable measurements.

Download the White Paper

A succinct review of what is needed to make edge break measurements a value-adding operation. Evaluation of this critical feature can be a means to improve productivity, increase the number of passed parts, and decrease costs from waste and failures.

A succinct review of what is needed to make edge break measurements a value-adding operation. Evaluation of this critical feature can be a means to improve productivity, increase the number of passed parts, and decrease costs from waste and failures.

Download the PDF now to see how and learn why it matters.

Added Technical Resources

3D shop floor characterization of radii and chamfers

A published paper on how best to get a measurement from a chamfered surface or a corner that needs edge break.

Developing Chamfer and Edge Break Measurements

Manufacturers of many types can benefit from measuring edge break. To help those customers, we are testing our Edge Break application for 4D InSpec.

Demo of edge break measurements

This webcast is a demo of edge break, and a lively discussion of the parameters needed to qualify edge break. It’s not just a radius, but how well centered it is on the edge, and the geometry of the materials adjacent to the edge.

Shop floor measurements of edge break and defects made easy

This webcast is an online demonstration of edge break, and defect on surfaces.

Learn more about the products

4D InSpec

4D InSpec provides non-contact measurement of surface features and defects, on the factory floor, in machine shops and in field service applications.

4D InSpec XL

A handheld defect inspection gauge that works like 4D InSpec standard, but with a larger field of view, to measure wider and deeper features.

InSpec Accessories

Accessories for improving portability, ease of use, or for accessing hard to reach measurements like sidewalls and through-holes.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed