Getting the most from a 4D InSpec.

Application Notes

In the App Notes offered here, our experts research customer questions, and explain properties of measurements by 4D InSpec. They provide instructions on how to make a better measurement, and explain complex metrology issues, because we believe better understanding makes a better world.

Don’t see what you need? Contact us with your question! If it’s something a lot of people ask us, we may turn the answer into an App Note.

Learning How to Measure [Better]

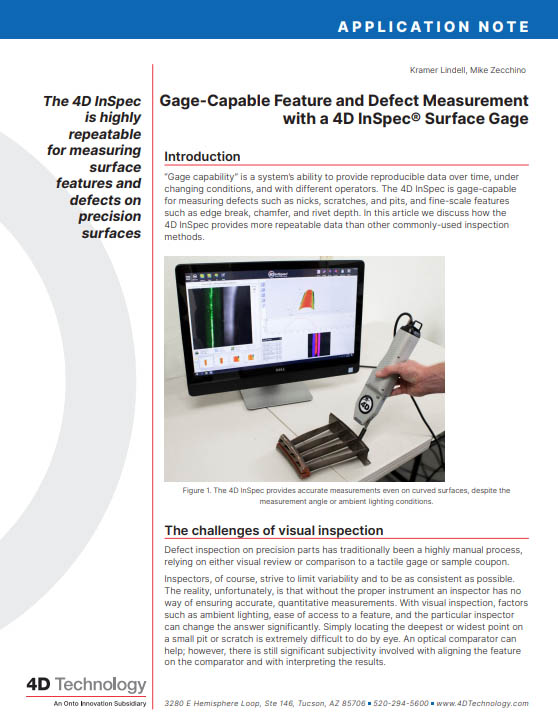

Gage-Capable Feature and Defect Measurement with a 4D InSpec® Surface Gage

This 4D InSpec application note presents a pair of repeatability and reproducibility studies: one on scratches and dents, and another on edge break chamfers.

SPOILER: 4D InSpec is more repeatable than other solutions.

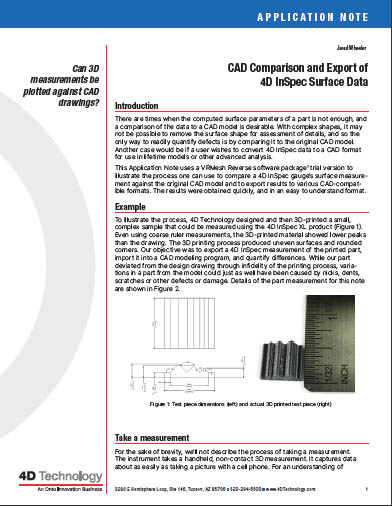

Take a 3D Measurement and Then Compare the Result to a CAD model

This 4D InSpec application note shows a simple example of exporting a 3D measurement from 4D InSpec as .XYZ, then importing that and the CAD file for the part surface in a third-party software package, comparing the measured part to the designed CAD model.

Measurements of Various Defects and Their Replicas Using 4D InSpec

This paper looks at how to use 4D InSpec with replica pastes and gels. It answers the questions of whether 4D InSpec measurements of parts and measurements of replicas correlate. And it advises when to use a replica, and when to just go ahead and make the measurement directly.

Measuring Highly Reflective Curved Surfaces with the 4D InSpec

Curved, shiny or smooth surfaces can be challenging to measure. The curves create highlights that can saturate the imaging sensor, making areas of missing data. This app note explains why this is, and how to adjust your measurement technique to get the data you need.

Step Limitations of Fringe-Based Measurement Systems

People often ask us why there’s a step limitation with 4D InSpec. It’s because the gauge uses a method of calculating heights that’s like the topographical lines on a map.

In this app note, we explain how come fringe-based measurement systems can only handle steps of limited heights.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed