Industrial Measurement

Handheld, shop floor, and automated surface metrology

With ultra-fast imaging times, many 4D products prove capable of measuring when attached to a robot, or even when handheld. These features mean industry technicians can gain high-precision surface data inside a production tool—for in-process updates—or on a turbine engine that’s still attached to an airplane wing—saving untold hours of dismantling.

Measuring a fan blade using a backpack-powered handheld surface gauge, 4D InSpec.

Industrial Measurement

Now: 3D, high resolution handheld

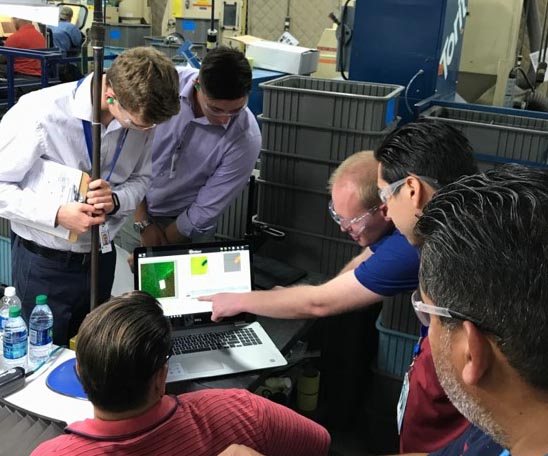

In the past, inspectors in many industries had to choose between inexpensive, but low-resolution surface gauges or high-resolution metrology instruments that required controlled measurement labs and cost many time more. 4D gauges offer the best of both worlds: high-resolution, 3D measurements with one-button operation that can be used anywhere in the factory or lab.

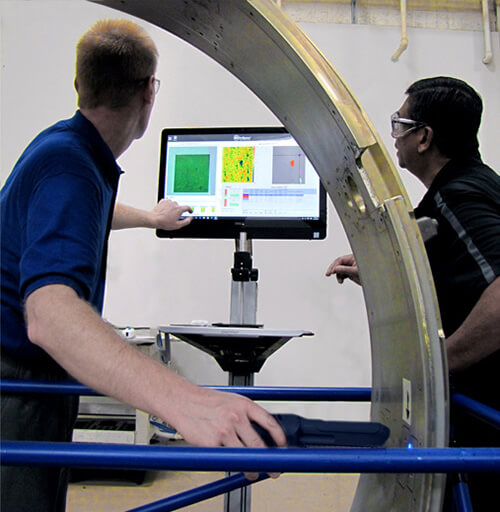

Measure in the shop, right now

The days of parking parts in a measurement lab queue are over. Now you can measure peen marks, edge break and more on the shop floor. Quantify defects on components and assemblies, anywhere in the shop. And determine the features of paint layers that truly lead to outstanding finishes.

Versatile, long standoff has reach

4D gauges make 2D profile measurement a thing of the past, providing many high-resolution, 3D surface maps in the time it takes to set up and acquire one low-resolution 2D profile trace.

Portable and compact, measuring in challenging locations, or at difficult angles is easy, without the time, mess and expense of using replication materials.

With its long stand-off, you can use a fold mirror to sample hard to reach spots in real time.

4Di automated measurement systems combine 4D InSpec surface gages with collaborative robots and other automation. Rapidly measure surface quality and features with high precision to improve measurement throughput, reduce scrap and rework, and improve quality with more thorough inspections.

Industrial Challenges

Aerospace and Defense

Aerospace and defense contractors rely on 4D Technology’s dynamic laser interferometers and optical profilers for accurate measurements.

Aviation and Automotive

Part inspection for high value machinery like aircraft engines requires high-volume, in situ defect qualification using non-contact 3D imaging of features.

Bio-Medical

Medical applications and biological research present a challenging set of requirements for measurement systems, including constantly changing subjects, difficult environmental conditions, and stringent controls, particularly for in vivo measurement.

Optics Manufacturing

4D Technology dynamic laser interferometers enable precision measurement right on the factory floor, without vibration isolation.

Semiconductor

Semiconductor manufacturers count on 4D measurement instruments to ensure quality throughout the manufacturing process.

New Developments

Keeping up with our customers’ needs is a full time job.

You move fast. We move faster, because dynamic interferometry® is all about speed.

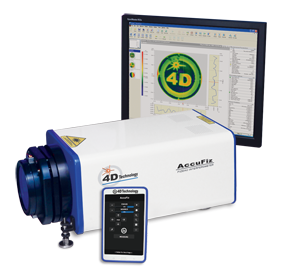

Dynamic on-axis Fizeau

Low error, high speed

click to Learn more

-

Stop-action dynamic measurements

-

On-axis image eliminates retrace error

-

Compatible with beam expanders

Service contracts

Keeping your instrument in shape

Click to Learn More

With options like:

- Call center support

- Remote diagnostic services

- On-site response

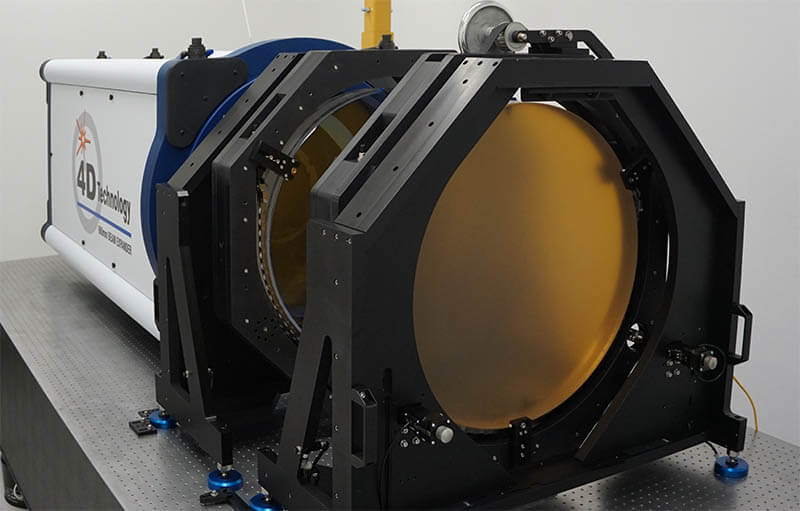

Bigger better beam expanders

Convenient and versatile, with precision

Click to learn more

-

No fold mirrors for best precision

-

Kinematic interferometer mount saves realignment

-

Lightweight carbon fiber structure helps reduce thermal expansion error

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed