How Gage Capable is the 4D InSpec?

Proven results

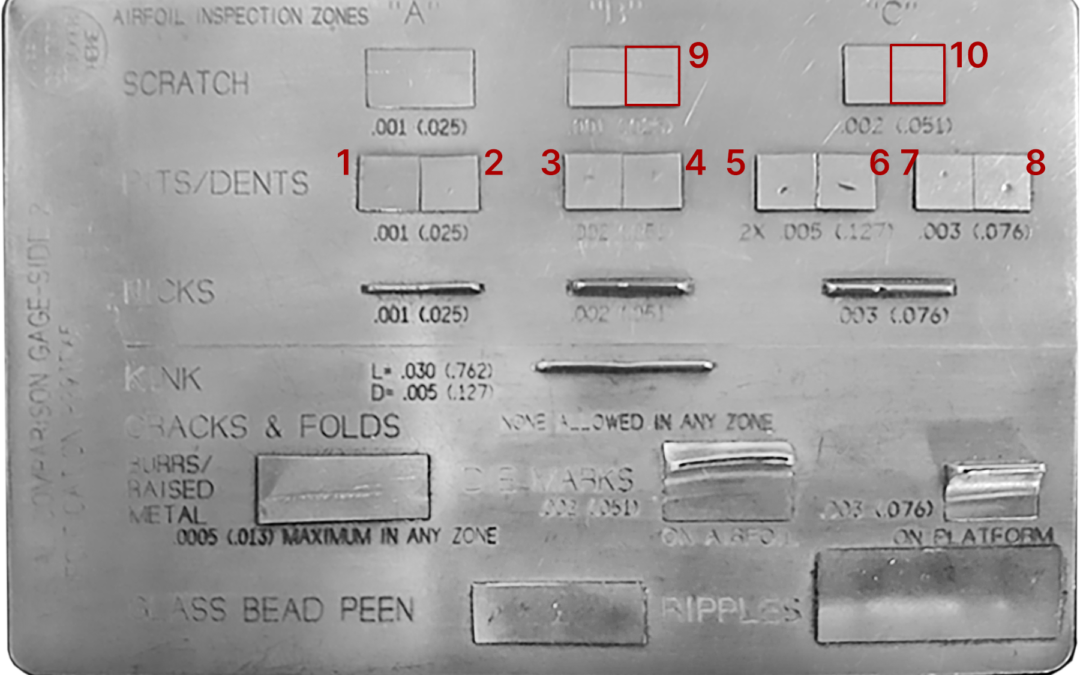

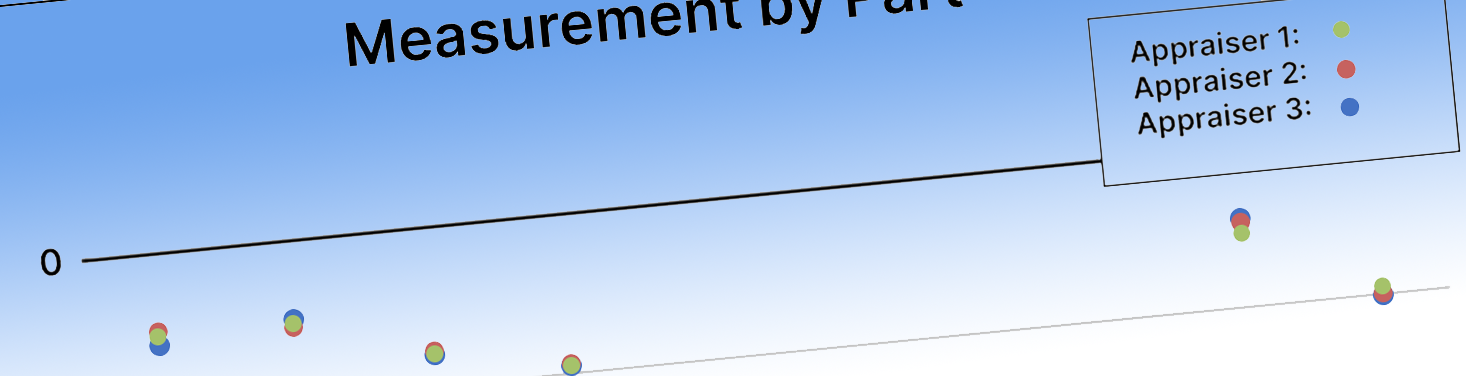

The 4D InSpec is gage-capable for measuring defects such as nicks, scratches, and pits, and fine-scale features such as edge break, chamfer, and rivet depth. In this article we discuss how the 4D InSpec provides more repeatable data than other commonly-used inspection methods.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed