White Paper: Precision in Your Palm

5 Reasons 3D Handheld Optical Gauge are Taking Over the Shop Floor

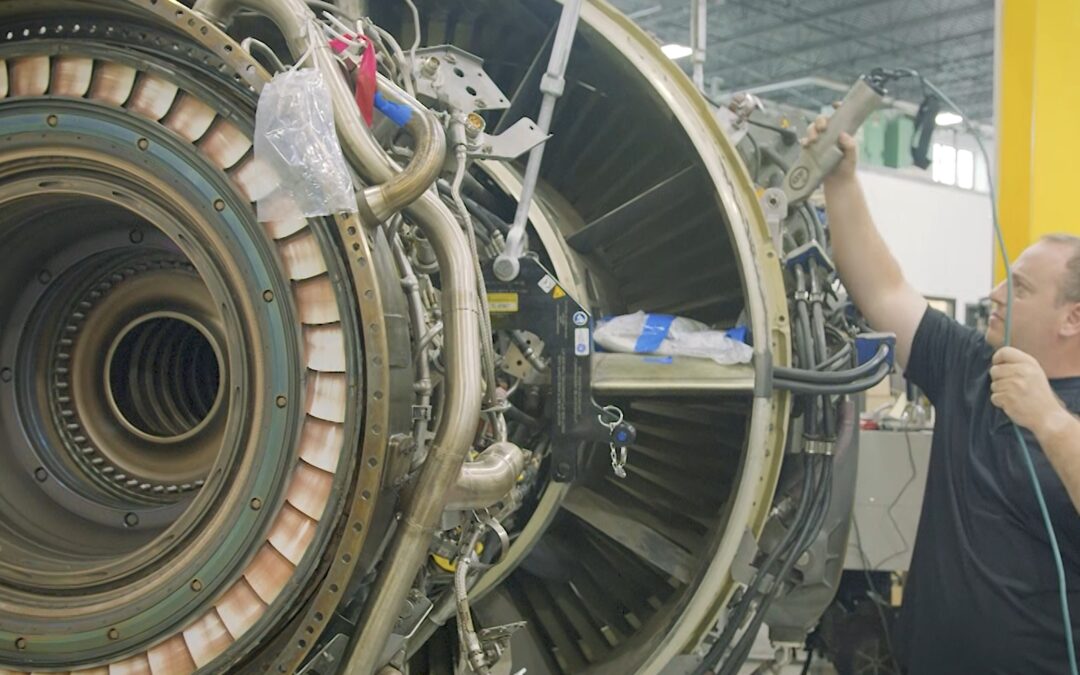

In the aerospace industry, precision is not optional. The quality and geometrical accuracy of components like turbine and compressor blades directly impact engine performance, efficiency, and reliability. Even minor deviations in shape, surface texture, or geometry can lead to increased fuel consumption, reduced power output, or premature failure under extreme operating conditions.

This white paper highlights how handheld 3D optical gauges, and specifically the 4D InSpec, are helping the industry solve persistent challenges in part validation, measurement accessibility, and process control. Included are five key reasons why these companies, and many of their peers, are making the switch.

- Reason 1: Traditional inspection methods hold you back

- Reason 2: Fixed systems can’t reach every surface

- Reason 3: Portability unlocks shop-floor efficiency

- Reason 4: Stylus measurements introduce too much variability

- Reason 5: Slow inspections are costing you more than you think

Whether you are evaluating options or need a case to select 3D optical, handheld shop floor measurement system, this is the paper to download now!

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed