Custom Metrology solutions

Tap 4D’s expertise and innovation to solve difficult metrology challenges.

4D custom interferometers and laser interferometers overcome difficult environments, complex setups and one-of-a-kind measurement problems, at wavelengths from DUV through IR.

Custom Interferometers from DUV Through IR

4D Technology has driven recent major advances in interferometry including polarization-based phase shifting, short coherence laser interferometry, vibration-insensitive speckle interferometry and many others.

4D’s custom interferometers and other custom metrology solutions let you tap the creativity and expertise of our team to solve your metrology challenges. 4D custom interferometers and laser interferometers overcome difficult environments, complex setups and one-of-a-kind measurement problems, at wavelengths from DUV through IR.

4D also provides the service and support to ensure that our custom systems give you the same reliability you expect from 4D products.

“The 4D Technology interferometer has enabled us to make measurements that were not previously possible, including measurements that are crucial to the success of the James Webb Space Telescope Project. The 4D system has exceeded our expectations.” -Babak Saif, Space Telescope Science Institute

Custom Wavelengths

4D has constructed custom interferometers from 193 nm through 10.6 microns wavelengths, and everything in between.

New Applications

4D’s innovative sensors and Dynamic Interferometry® technology help researchers and engineers in diverse fields from From biology to lithography.

Challenging Environments

4D has developed one-of-a-kind solutions to adapt to all kinds of adverse environments, from interferometers for cryogenic chambers to polarization cameras for field research.

A Range of Industries

4D solutions help manufacturers spot defects in high-speed production lines, image unique optics, and unlock the secrets of the universe with metrology for the world’s premier astronomy and space-based telescopes.

Sample Projects

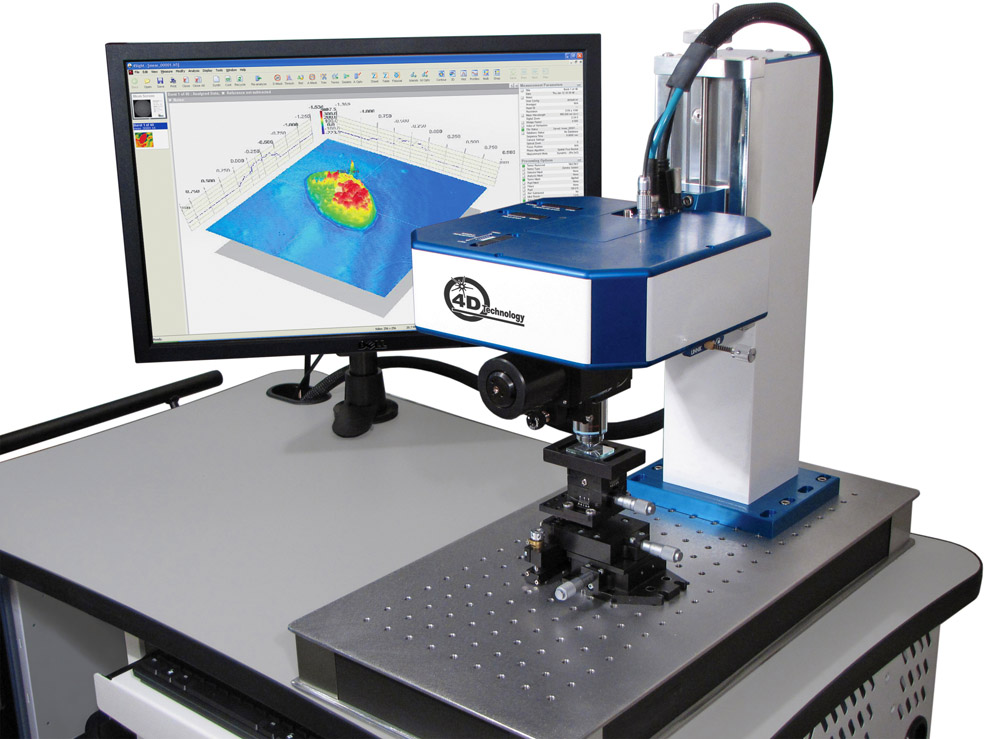

Based on the unique capabilities of the NanoCam Optical Surface Profiler, The BioCam Quantitative Phase Microscope lets researchers measure cell motion and dynamics at video rates within and among live cells.

Dynamic Interferometry® provides fast acquisition that enables cell imaging in real time, at video rates, to track cellular motion and changes in cell volume. The method offers sharper cell imaging, faster acquisition and faster analysis time than other methods such as digital holography.

The BioCam uses low light levels to avoid phototoxicity and does not require contrast agents, enabling researchers to measure the volume, optical thickness and dry cell mass of live cells and to follow motion and processes over time. This data provides valuable information to researchers studying cellular dynamics, motility, and cell and tissue morphology.

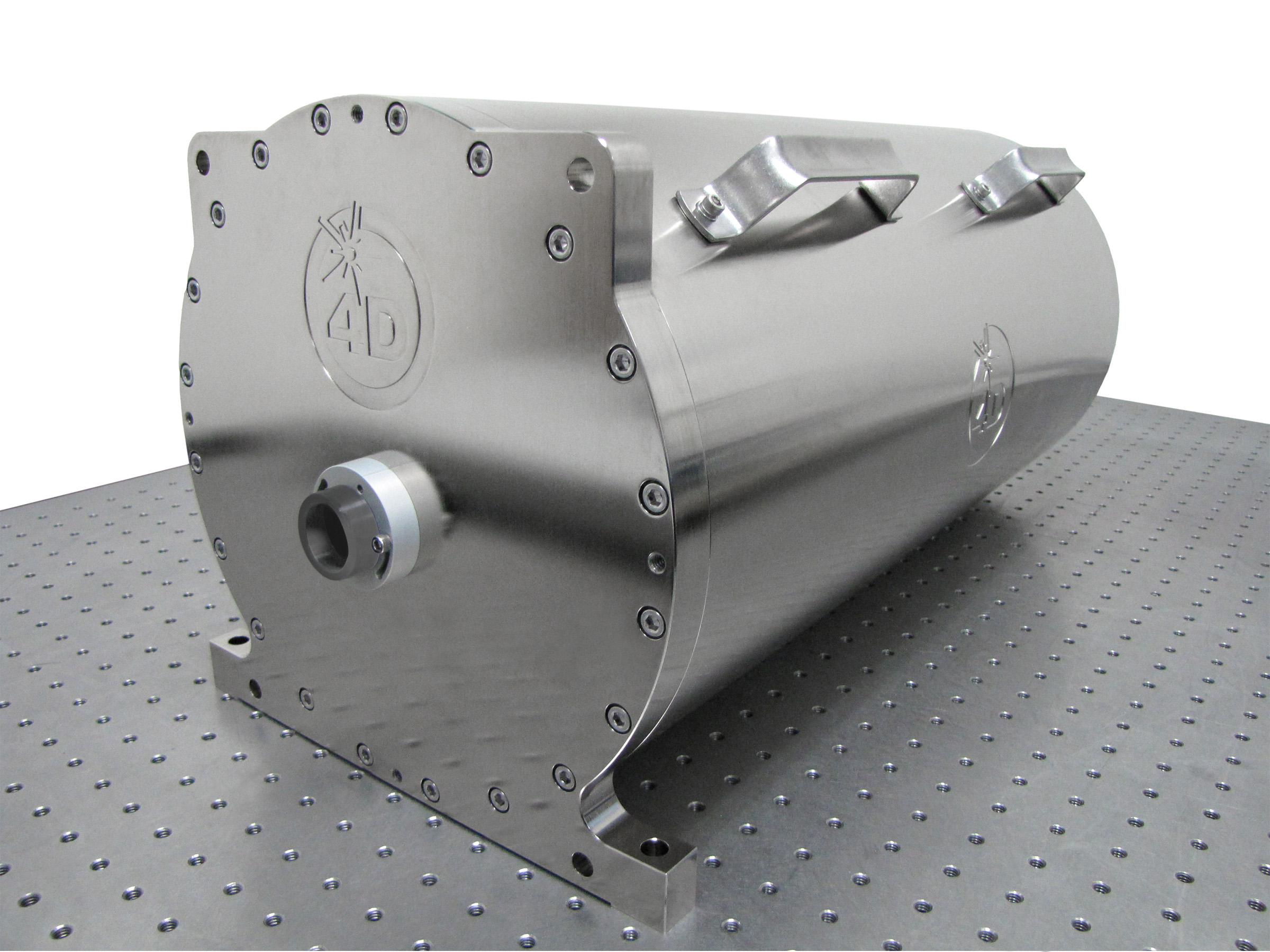

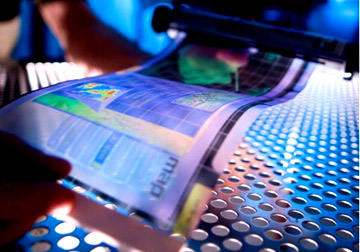

Microlithography applications require near-perfect optical component quality at deep ultra-violet (DUV) wavelengths. The operating environment for manufacturing DUV optics is very challenging due to high vibration and air flow, and extreme clean room requirements.

The FizCam DUV dynamic laser interferometer was developed to provide accurate measurement of optics and optical systems at DUV wavelengths. The system incorporates a single camera, high-speed optical phase sensor that makes a wavefront measurement in less than 1 millisecond. Because acquisition time is so short, the FizCam DUV can measure accurately despite heavy vibration and air flow, as is typical of DUV compliant clean rooms.

Built to the stringent specifications of DUV optics manufacturing, FizCam DUV components are stainless/electroless nickel plated, and the laser path is entirely contained in a purged nitrogen environment.

Motorized controls were also added, including 2X discrete optical zoom, focus, polarization, input beam alignment, transmission flat tip/tilt and optional return flat tip/tilt.

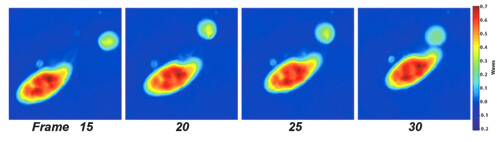

Engineers developing the James Webb Space Telescope needed to test the stability of the back-plane structure for the spacecraft’s primary mirror. This large, diffuse structure would need to be measured from a significant standoff location, in the presence of vibration.

To meet the complex requirements 4D developed the SpeckleCam Electronic Speckle Pattern Interferometer (ESPI), which measures the change in shape of structures with diffuse surfaces. Its patented, single camera pixelated sensor enables high spatial sampling. The system is capable of measuring meter-class structures with an acquisition time of 9ns which is six orders of magnitude shorter than the acquisition time for conventional interferometers. Rapid data acquisition permits accurate testing and quality control without the need for costly vibration isolation hardware.

SpeckleCam can measure the deformations of the entire surface simultaneously without attaching auxiliary optics to the test article. The SpeckleCam system provides sufficient energy in the illumination to measure meter-class structures.

With the SpeckleCam, a baseline measurement is made, then subsequent measurements are compared to it, to determine deformation. Measurements can be made synchronously or asynchronously with respect to object motion. For measurement of vibrational deformation, synchronous capture can examine changes over a wide frequency and phase spectrum.

The backplane structure for the James Webb Space Telescope primary mirror (Courtesy Northrop Grumman ATK Space Systems)

Do you need custom-built metrology?

Get a free consultation. 4D Technology’s mechanical, optical, electrical and software engineering teams are standing by to evaluate what it would take to meet your application’s requirements.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed