MEMS

Micro-Electro-Mechanical Systems

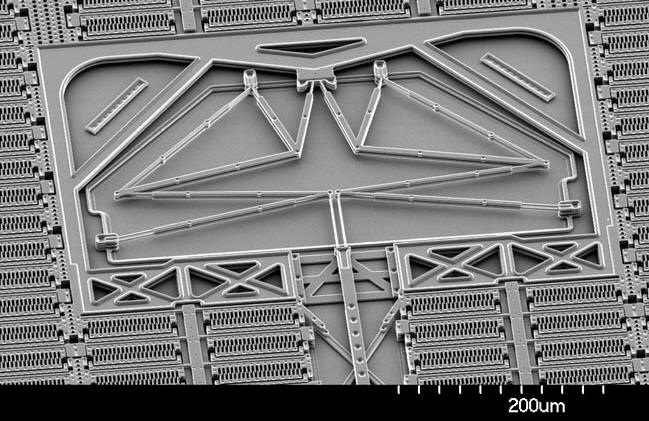

MEMS (Micro-Electro-Mechanical Systems) consist of miniaturized mechanical and electro-mechanical elements which are manufactured using various deposition and etching techniques. MEMS devices range in size from sub-micron to several millimeters and vary from relatively simple structures having no moving elements, to complex systems with many moving elements. These systems are interchangeably referred to as MEMS, microsystems or micromachined devices.

One of the primary family of MEMS structures are microsensors, which convert mechanical signals into electrical outputs. These miniature transducers measure temperature, acceleration, pressure, force, rotational velocity, humidity, sound, magnetic fields and other parameters.

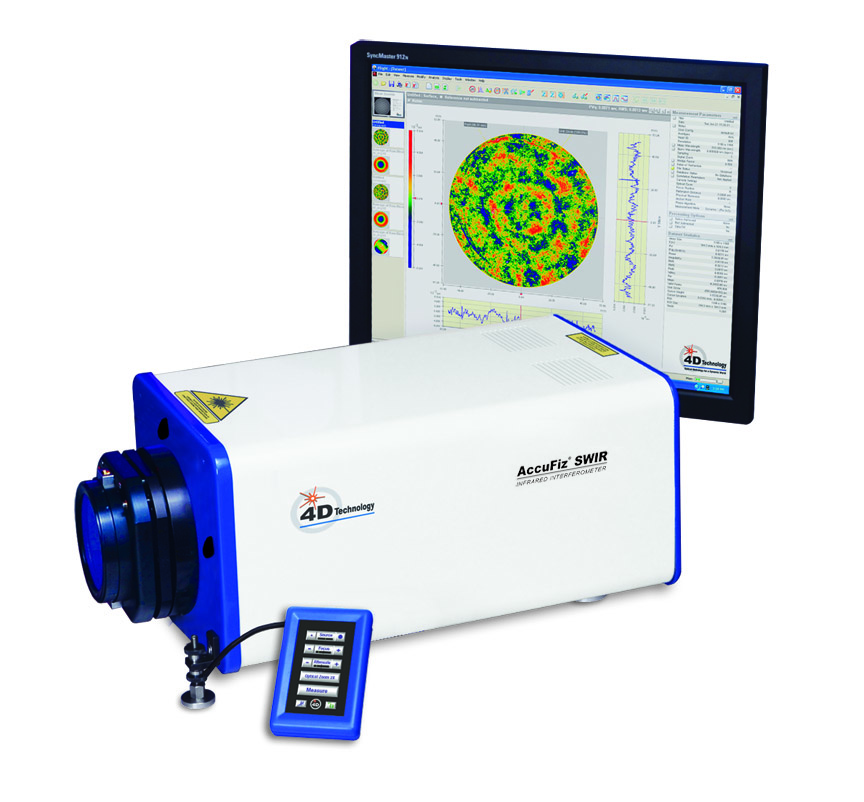

4D AccuFiz Fizeau interferometers measure flatness and roughness of wafers.

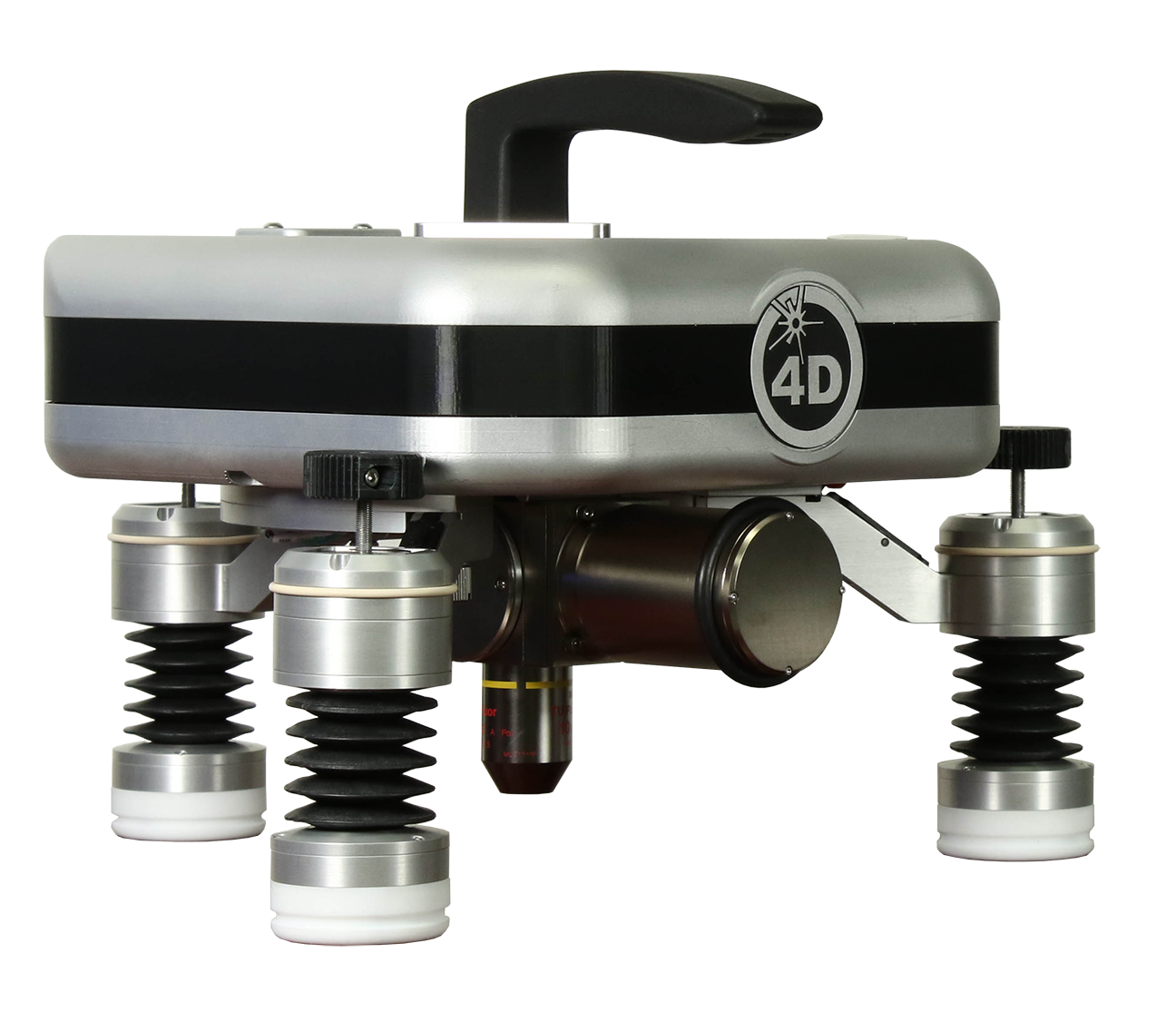

NanoCam HD optical profilers measure roughness on coated and uncoated wafers. NanoCam HD can also measure the shape and shape change of wafer-level devices (such as microfluidics) and diced and packaged devices (such as micromirror arrays).

Added Technical Resources

Measuring Sub-Angstrom Roughness

How do you measure roughness with sub-angstrom precision in a noisy manufacting environment?

Read this white paper for a break-down of the options, and illustrations of the challenges presented by different solutions.

Products for MEMS

AccuFiz

Fizeau laser interferometer for fast, repeatable measurement of wafer flatness.

Optical Profiling

NanoCam HD systems measure surface roughness on coated and uncoated wafers as well as measuring devices on patterned wafers.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed