Opthalmic

Contact lenses manufacturers rely on accurate measurement of radius of curvature of lens molds and of lenses throughout production. The steep slopes and sometimes strongly aspheric shape of both the molds and lenses require high resolution a measurement system. Measuring thin, transparent lenses also proves challenging for standard interferometric instruments as reflections from both surfaces combine to render the data unusable. Add the space constraints and high vibration of production environments and these measurements prove to be exceptionally challenging.

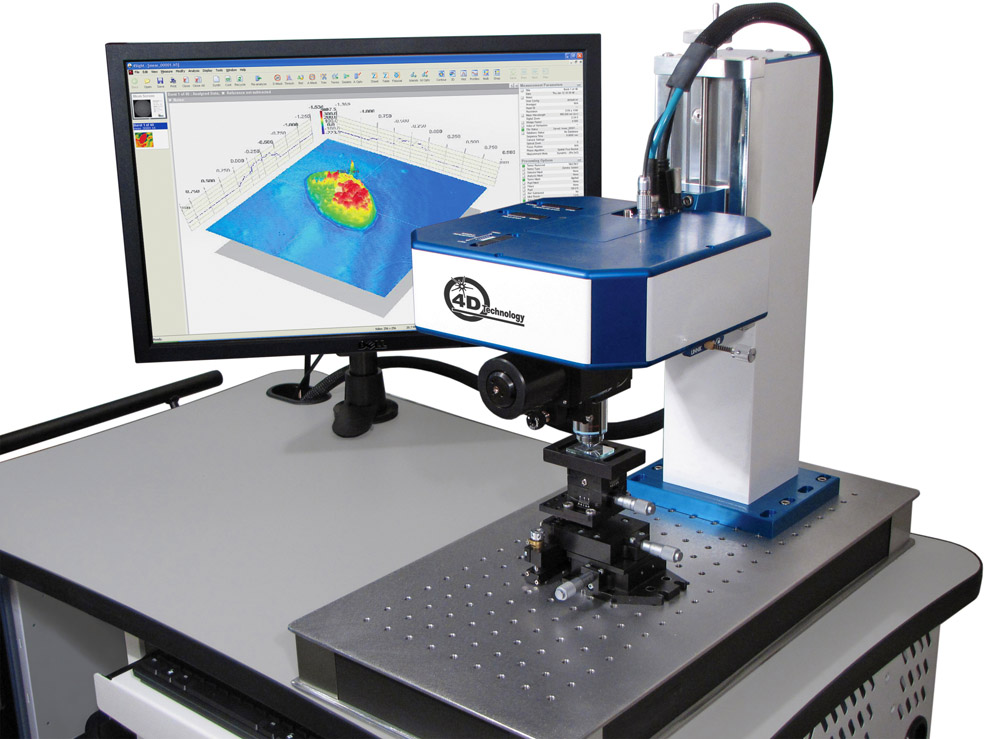

4D has custom engineered systems to aid in the production measurement of contact lenses and lens molds. High resolution measurement of radius of curvature ensure adherence to the strict tolerances of lens prescriptions despite steep slopes. Short coherence sources enable measurement of both lens surfaces and optical thickness in a single setup to ensure fit and prescription. By employing dynamic interferometry these custom systems can measure despite vibration for accuracy in production environments.

Products for Opthalmic Applications

Custom Solutions

Custom engineered systems aid in the production measurement of contact lenses and lens molds. Accurate measurement of radius of curvature and optical thickness ensures adherence to prescription.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed