Measuring Turbine Blades

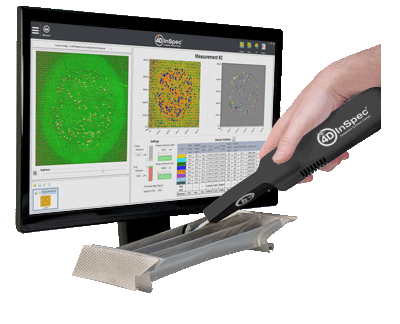

Measuring a turbine blade with 4D InSpec is an easy matter. You may inspect a wide range of blade elements and features with high versatility:

- Deformations of blade edges

- Surface defects

- Defects between blades

- Radius of curvature

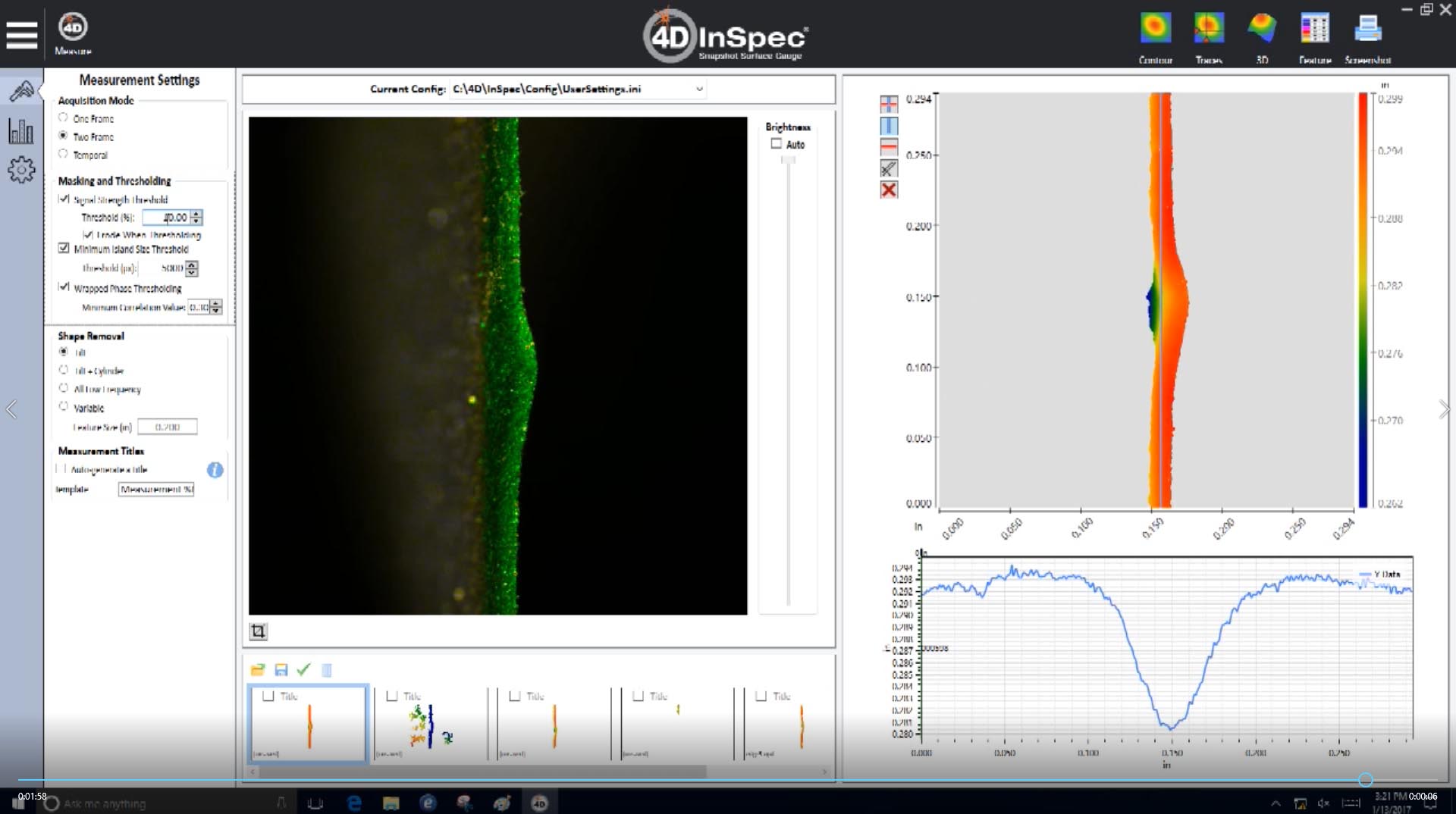

Blade Edge Measurements

Grooved focus aids help you hold 4D InSpec in alignment with a turbine blade edge. From a measurement, you can quantify dents and deflections from damage.

Surface Defects

Automated feature analysis can be used to isolate and quantify different kinds of defects found in a measurement.

Defects Between Blades

Use a fold mirror to measure surfaces between closely placed blades.

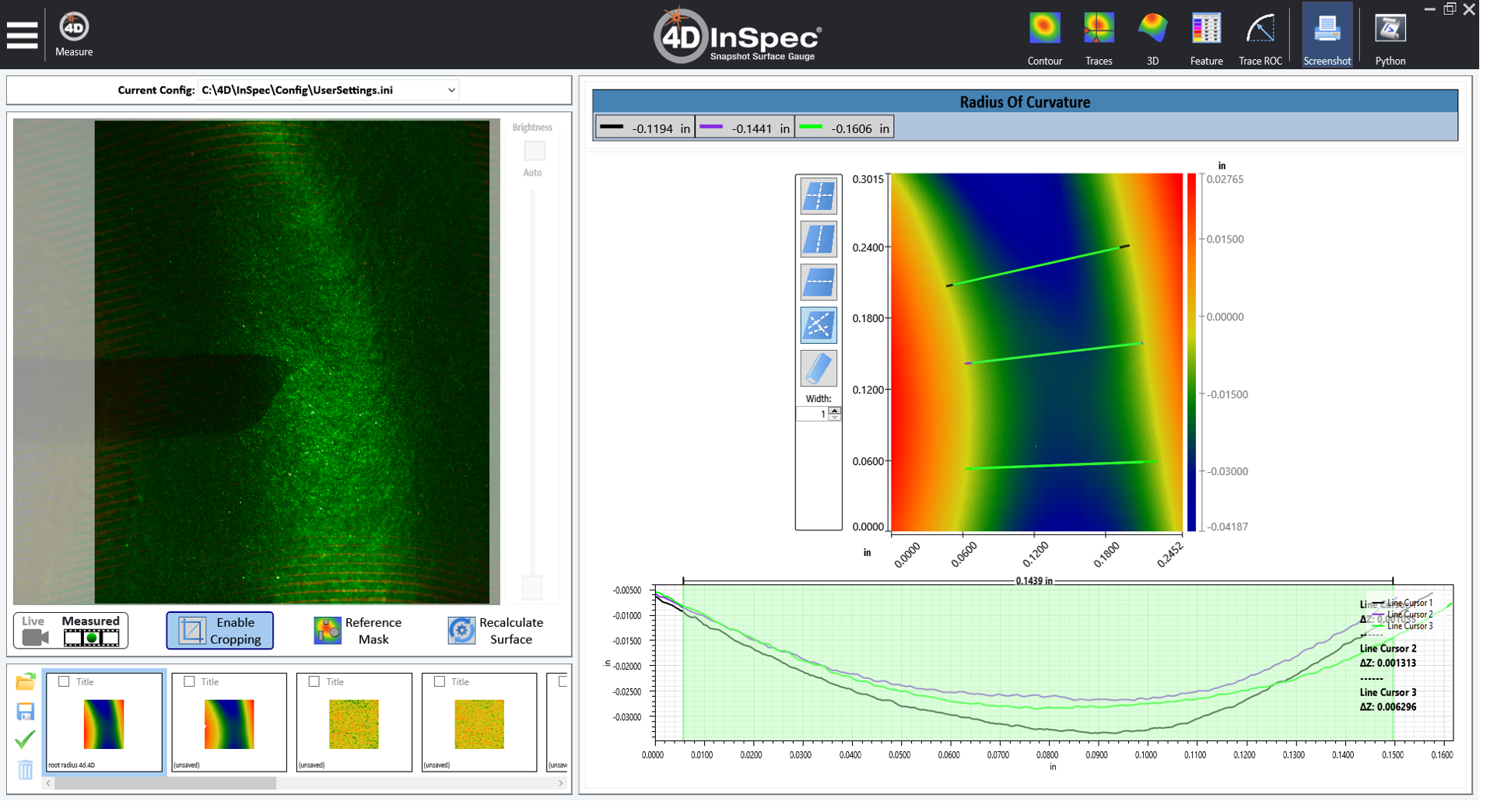

Radius of curvature

The photo below shows an area of curvature, and a measurement that calculates the radius of curvature in the joint.

Added Technical Resources

Measuring Turbine Blade Surface Defects

Step by step video guide shows how quick and easy it is.

Learn more about the products

4D InSpec

4D InSpec provides non-contact measurement of surface features and defects, on the factory floor, in machine shops and in field service applications.

4D InSpec XL

A handheld defect inspection gauge that works like 4D InSpec standard, but with a larger field of view, to measure wider and deeper features.

InSpec Accessories

Accessories for improving portability, ease of use, or for accessing hard to reach measurements like sidewalls and through-holes.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed