4D Inspec for fanuc crx collaborative robots

Vastly improve inspection throughput and quality in aviation, aerospace, medical, automotive, and other applications.

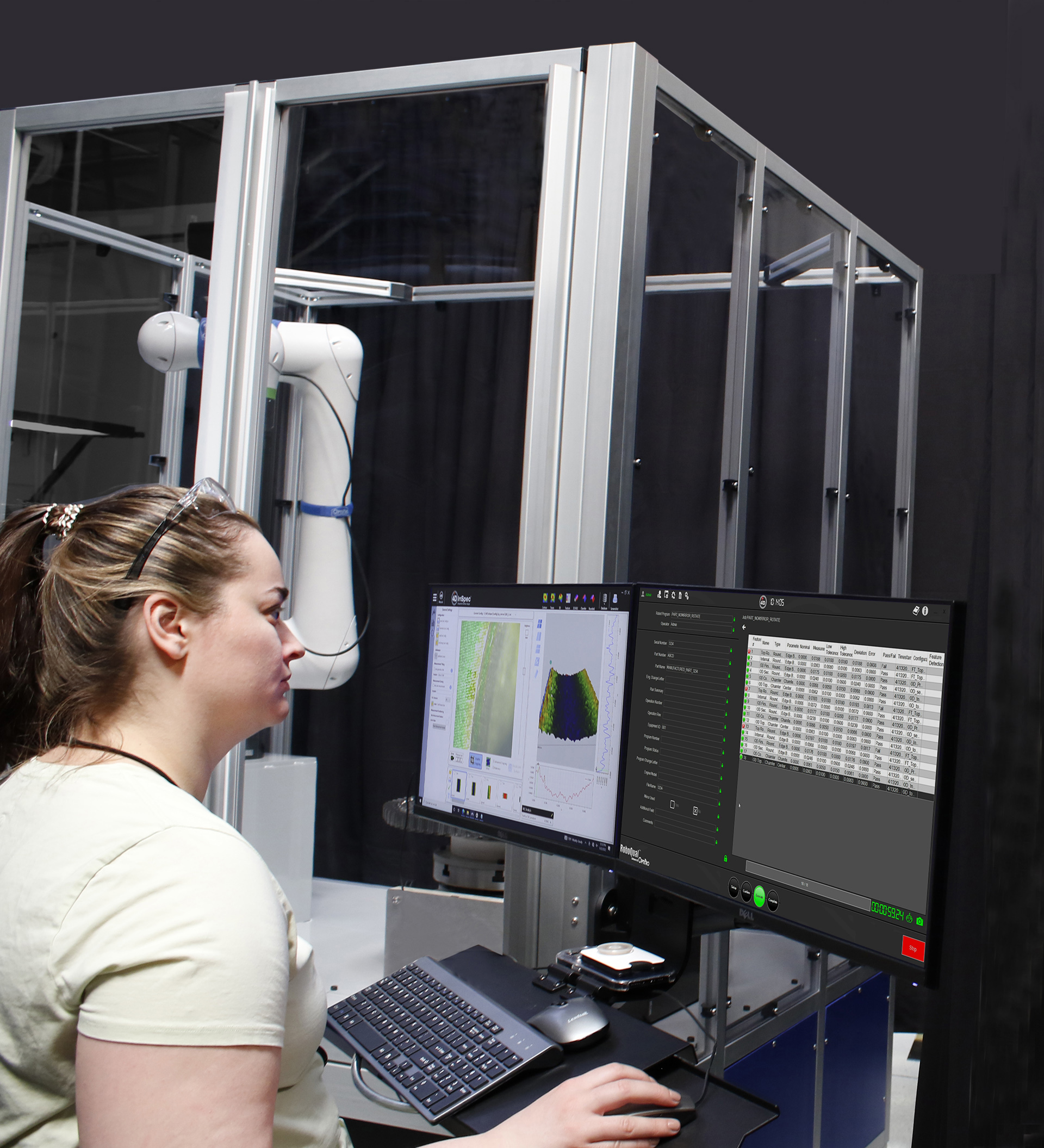

Automated 4D InSpec measurements enable a high-throughput, high-resolution defect and feature inspection solution. An automated system can measure dozens to hundreds of edge break features, chamfers, and defects in minutes rather than days, vastly improving throughput and driving down inspection costs.

Maximize process yield and quality

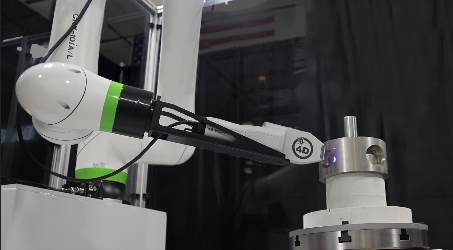

4Di InSpec automated systems combine a non-contact 4D InSpec or 4D InSpec XL surface gage with a Fanuc collaborative robot and other automation for rapid production inspection.

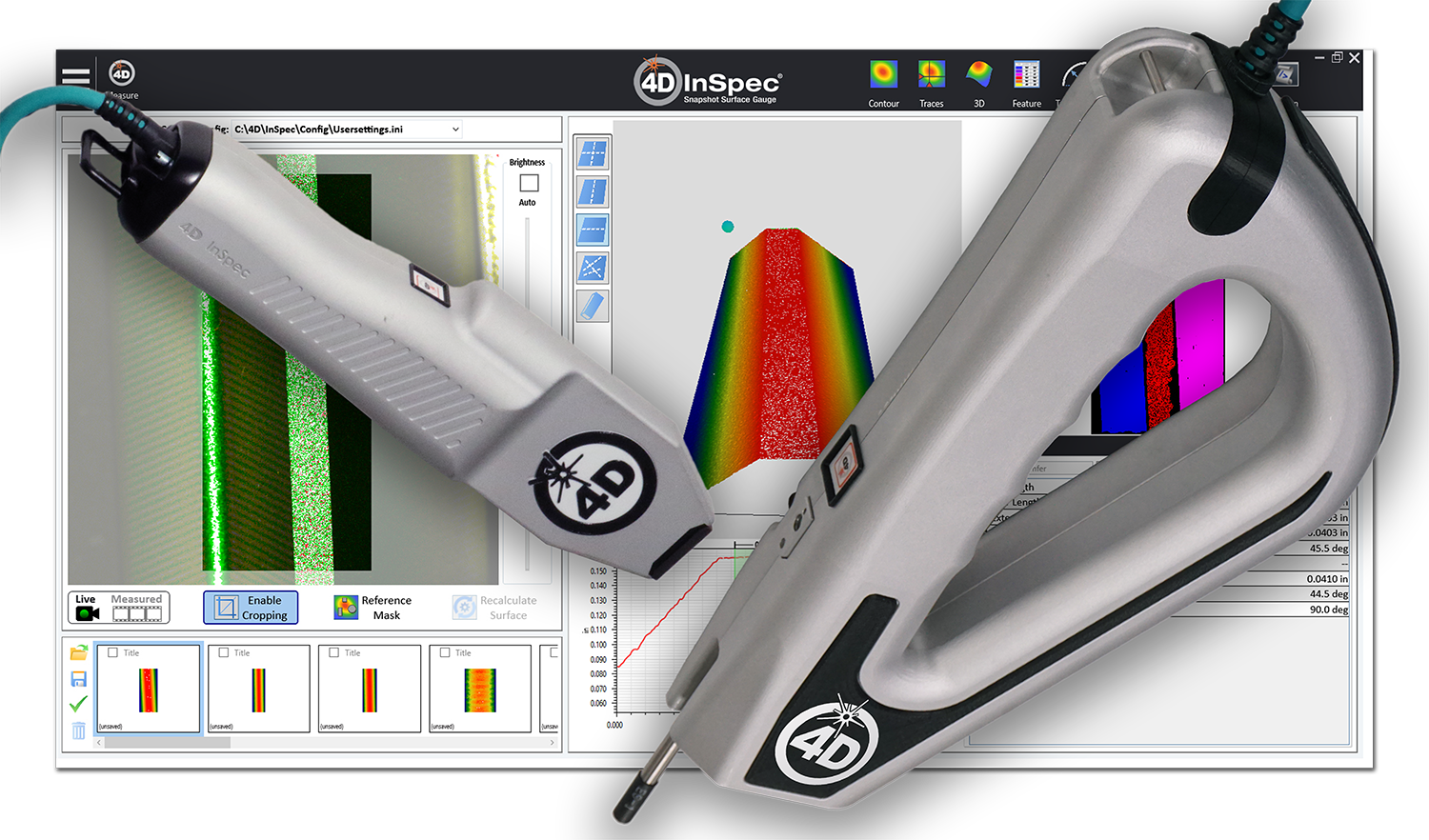

4D InSpec is the first precision instrument for non-contact surface defect measurement. Micrometer-level resolution, measurement in seconds, and immunity to vibration make it the tool of choice for high-resolution, 3D surface measurement in manufacturing, MRO, and field service applications.

Choose the model

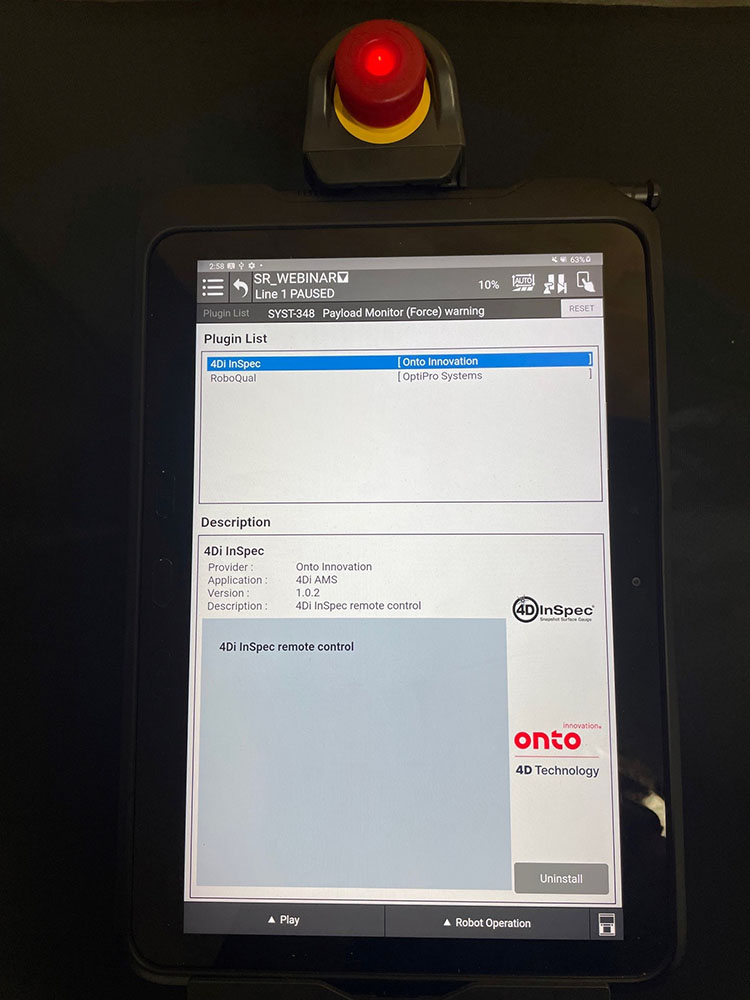

4Di InSpec Fanuc Plugin

4D software plugin that integrates the 4D InSpec functionality into the graphical user interface of the Fanuc tablet teach pendant for a fully automated 3D, optical surface inspection system to measure features such as chamfer, radius and edge break and defects such as pits, dings, scratches and corrosion.

-

- Easily automate 4D InSpec measurements

- Plug and play ready

- InSpec or InSpec XL gage

- Works with all Fanuc CRX cobots

4Di InSpec Fully Automated Systems

-

- For aviation and automotive manufacturing

- Inline design

- Fanuc CRX 5iA or CRX 10iA/L collaborative robot

- InSpec or InSpec XL gage

- Optional rotary table

- Mount gage or workpiece on robot

- Measurement automation software

- Safety cell

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed