Additive Manufacturing Industry

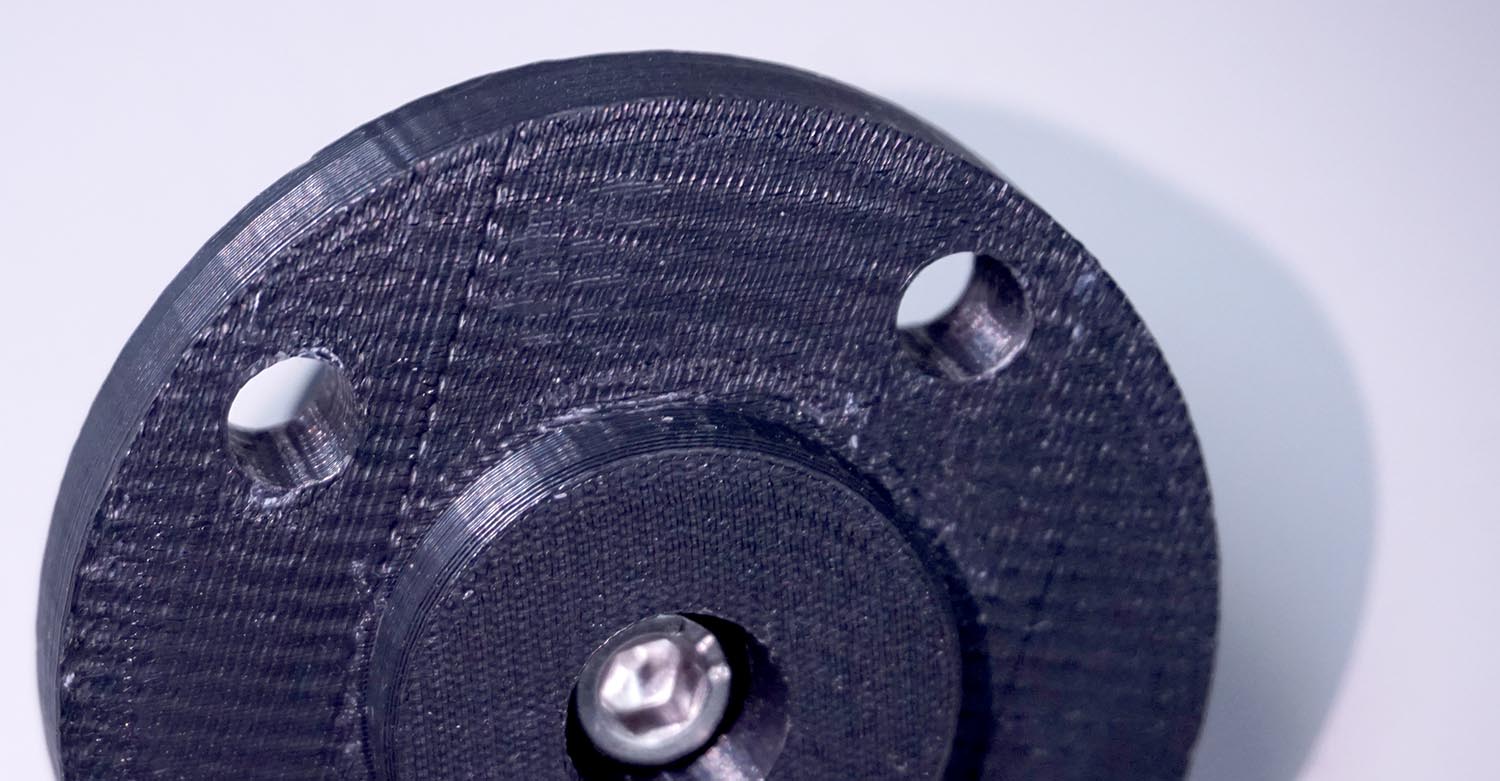

Testing texture and looking at defects

The 4D InSpec can instantly measure features and defects from 0.1–100 mils (2 mm) deep on parts with challenging geometries, which makes it highly valuable for measuring 3D printed parts.

Will your part need sprue contact points removed? Will it need some post processing, such as sanding? Use the 4D InSpec to verify that your post processing was successful.

Metals and polymers

The handheld 4D InSpec inspection gauge uses a structured polarized light projection technique which is unhindered by materials or color. So whether your printing technique is sintered metal, or a polymer, using powders or extrusion, 4D InSpec can give you a high resolution measurement of the surface structure.

Learn more about the products

4D InSpec

4D InSpec provides non-contact measurement of surface features and defects, on the factory floor, in machine shops and in field service applications.

4D InSpec XL

A handheld defect inspection gauge that works like 4D InSpec standard, but with a larger field of view, to measure wider and deeper features.

InSpec Accessories

Accessories for improving portability, ease of use, or for accessing hard to reach measurements like sidewalls and through-holes.

Added Resources

Measuring Surface Features with High Resolution in Factory Environments

Because of the lack of rapid, accurate, shop floor measurement, inspectors often lack confidence in their assessments. The overly cautious estimations that result mean that rejection rates are typically much higher than necessary.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed