Homogeneity and Thickness

Optical Setups

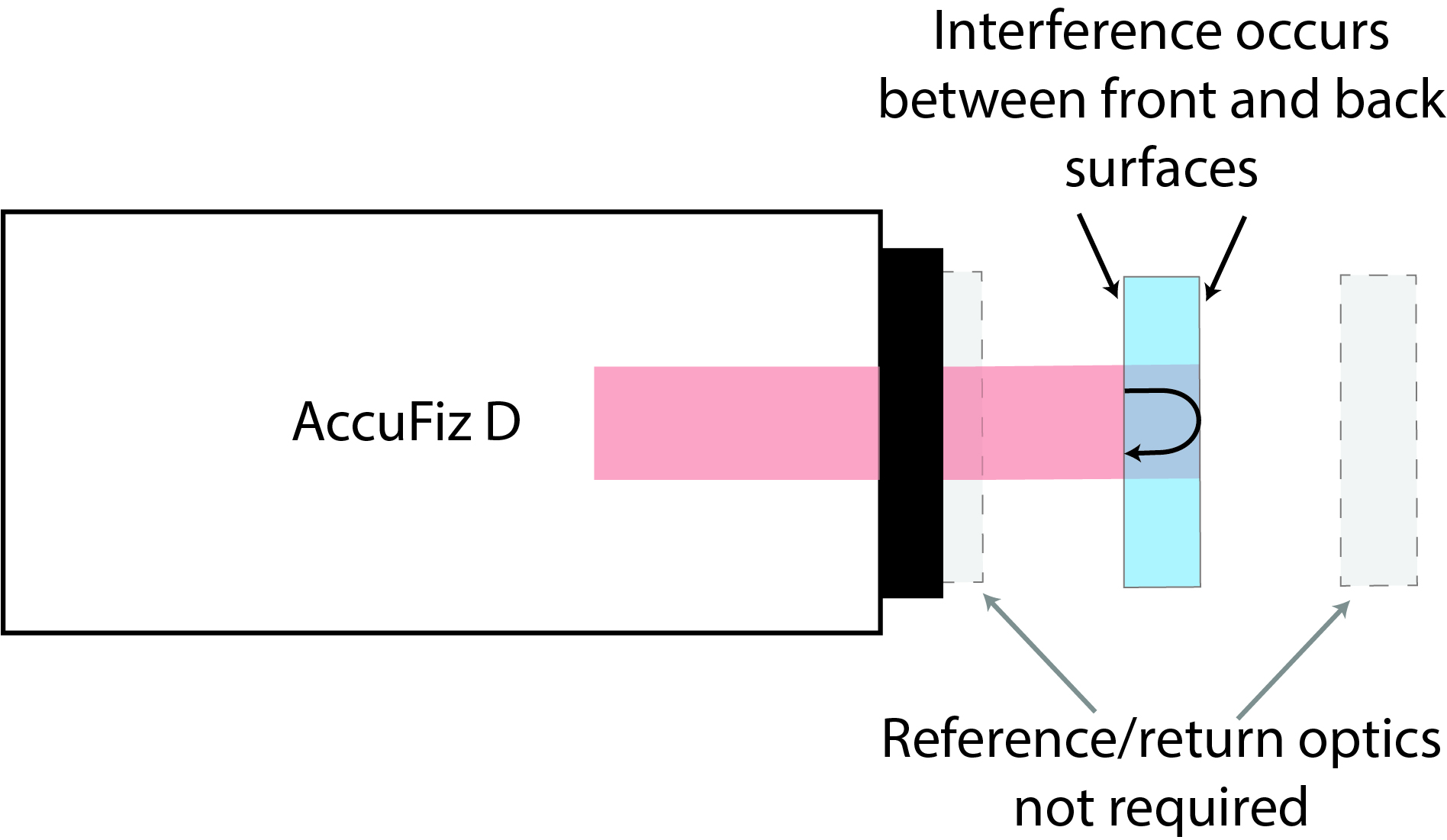

Homogeneity and Total Thickness Variation (TTV) can be determined from a series of laser interferometer measurements. While a standard Fizeau laser interferometer can be used, a short coherence interferometer can accomplish both jobs with fewer measurements, and without requiring sample surface treatments to isolate individual surfaces for measurement.

RECOMMENDED METHOD

Measuring Total Thickness Variation with a Short Coherence Fizeau Interferometer

Total thickness variation can be determined from a single remote cavity measurement, with the front and back surfaces of the optic being the reference and test surfaces.

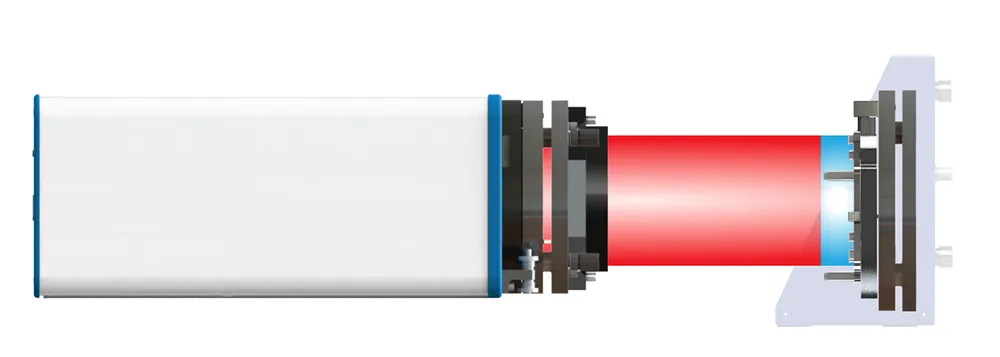

Solid cavity measurement setup for total thickness variation with a short coherence interferometer.

For the TTV measurement, the wedge factor should be 0.5. The OPD data is scaled by (-1/n) to calculate TTV.

Setting the Wedge Factor Tech Note

This tech note explains how to set the Wedge scaling Factor for measuring wavefront error and surface height in common configurations.

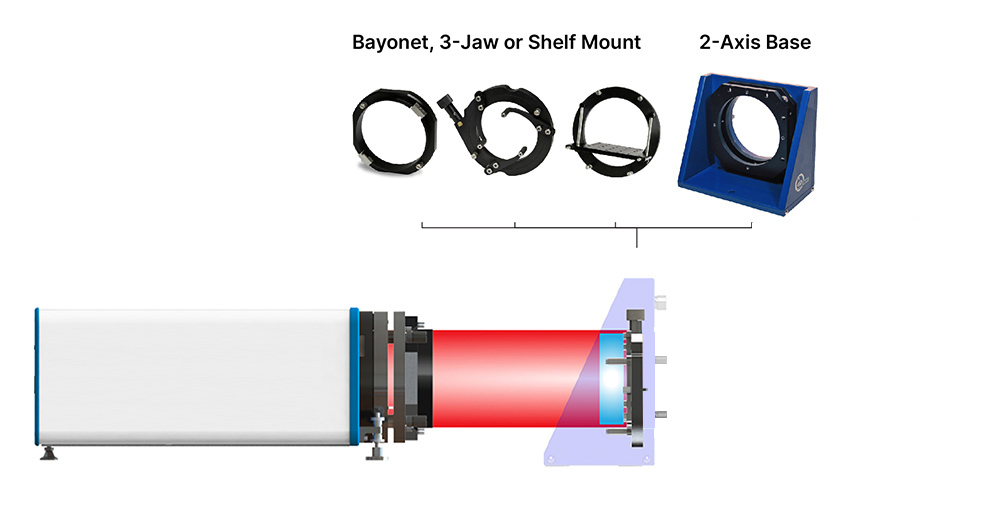

Required Equipment

| Required Components | |

| AccuFiz D Interferometer | More Information |

| Bayonet, 3-Jaw or Shelf Mount | Specifications |

| 2-Axis Base with Tip/Tilt | Specifications |

RECOMMENDED METHOD

Measuring Homogeneity with a Short Coherence Fizeau Interferometer

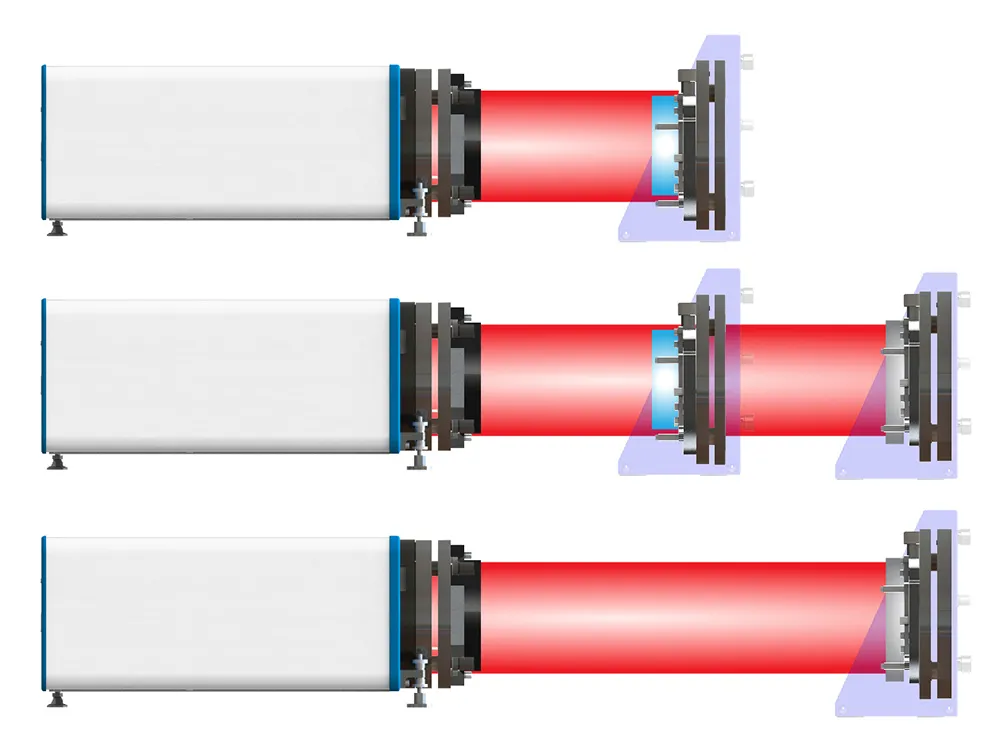

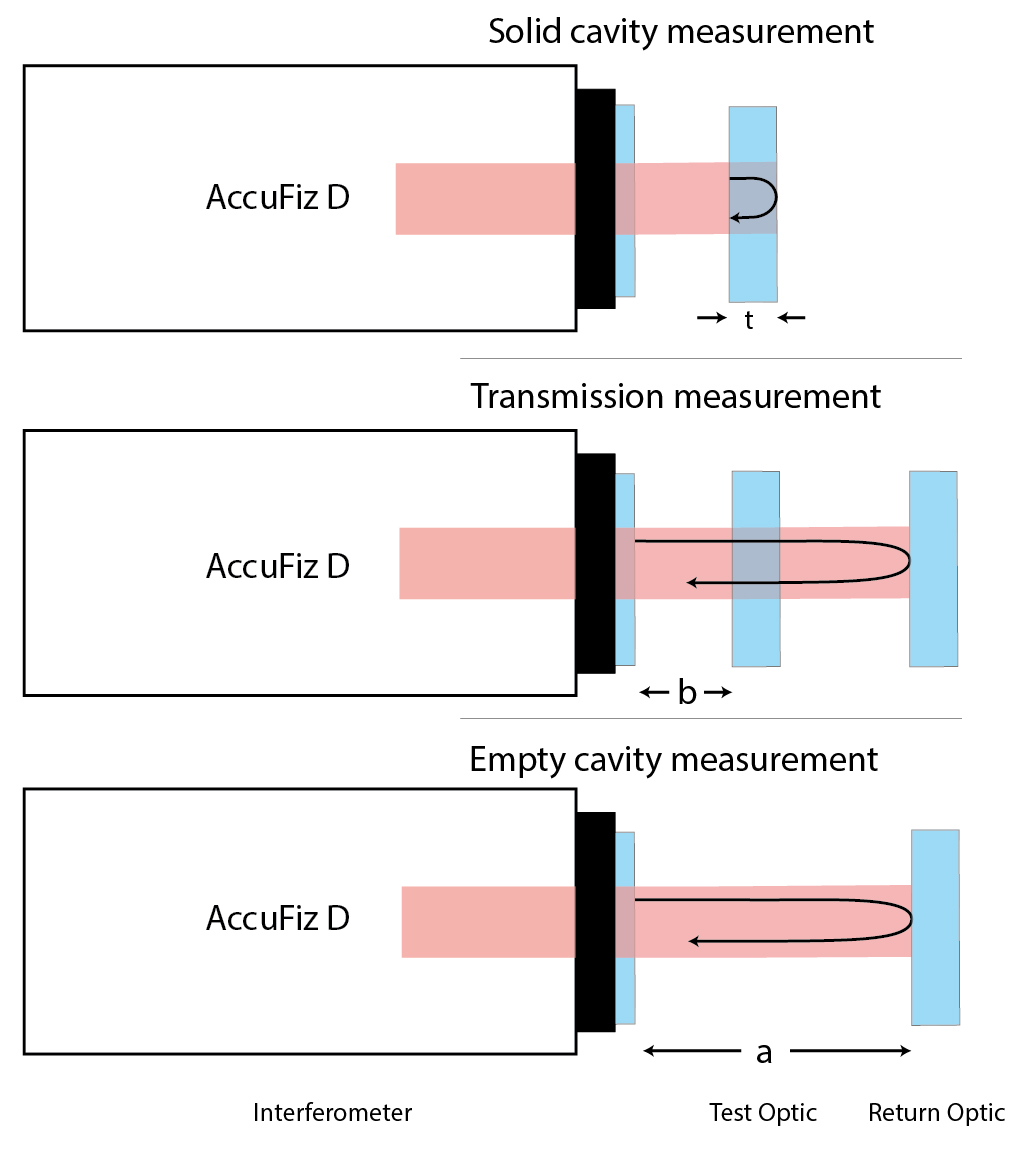

A traditional, long coherence interferometer requires four measurements to obtain homogeneity. With the short coherence AccuFiz D, only three measurements are needed:

- A solid cavity measurement, with the front and back of the optic as the reference and test surfaces.

- The transmission measurement, with a reference flat and high-quality return optic.

- The empty cavity measurement, with a reference flat and high-quality return optic.

The three measurements are acquired by adjusting the path match distance to the cavity length between the listed surfaces.

Setups for measuring homogeneity with a short coherence interferometer: solid cavity measurement (top), transmitted wavefront (center), empty cavity (bottom).

These measurements are shown schematically in the image below.

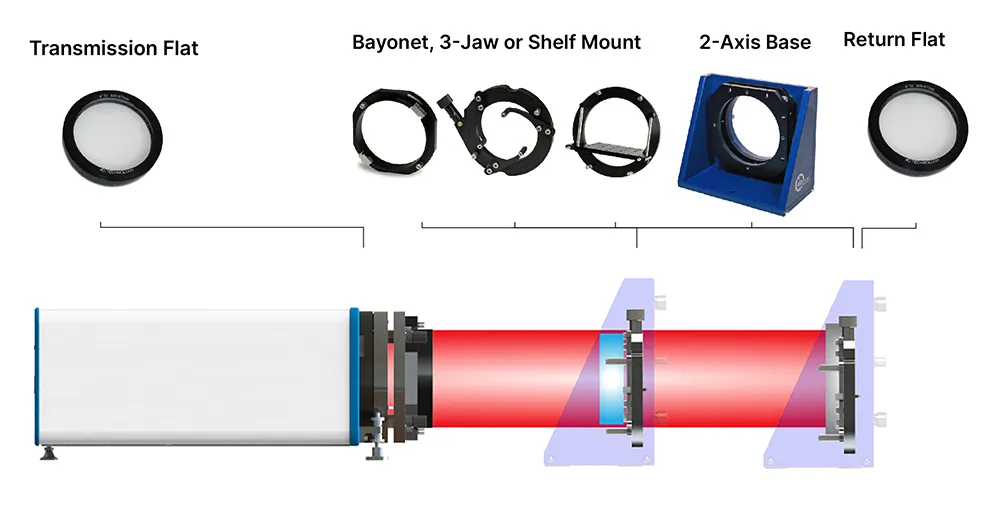

Required Equipment

| Required Components | |

| AccuFiz D Interferometer | More Information |

| Transmission Flat | Specifications |

| Bayonet, 3-Jaw or Shelf Mounts | Specifications |

| 2-Axis Bases with Tip/Tilt | Specifications |

White Paper - Space and Telescope Optics

Measurement of large optics requires metrology systems that can function despite vibration and other challenges. Learn how it’s done in this white paper.

ALTERNATE METHOD

Measuring Homogeneity with a Standard Fizeau Interferometer

- Additional measurements are required to complete the process.

- The test optic must be flipped between measurements which introduces sources of error. Considerable care is required to align the optics and reduce added error.

- The surfaces that are not being measured in a particular setup must be covered in anti-reflective coating in order to remove stray reflections—a messy and time-consuming process that can also potentially damage the optic.

Because of these complications, a short coherence interferometer is the preferred option for optical thickness and homogeneity measurements.

Need Assistance with Measuring Homogeneity or Optical Thickness?

Contact our applications staff today for expert opinions on optical measurement and on measurement equipment.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed