Wedge and Parallelism

Optical Setups

Overview

Verifying the wedge or parallelism of windows, reticles, glass discs, and domes, and glass, sapphire, or wafer substrates, is simpler and faster with a short coherence laser interferometer.

When measuring transparent optics with a traditional, long coherence source,, both of the surfaces can cause interference with the reference and with each other. The result is a complex interferogram which makes it difficult or impossible to measure the surface.

Traditionally, this problem has been addressed by applying an anti-reflective coating to one surface of a plane-parallel optic, removing its reflection so that the other surface can be measured. The coating is then removed and applied to the other surface so that the first can be measured. It is a messy, time-consuming operation that can damage the optic as well.

With the AccuFiz D short coherence Fizeau interferometer, the measurement can be made in a single setup, without the time-consuming coating process, as shown below.

RECOMMENDED METHOD

Measuring Wedge and Parallelism with a Short Coherence Fizeau

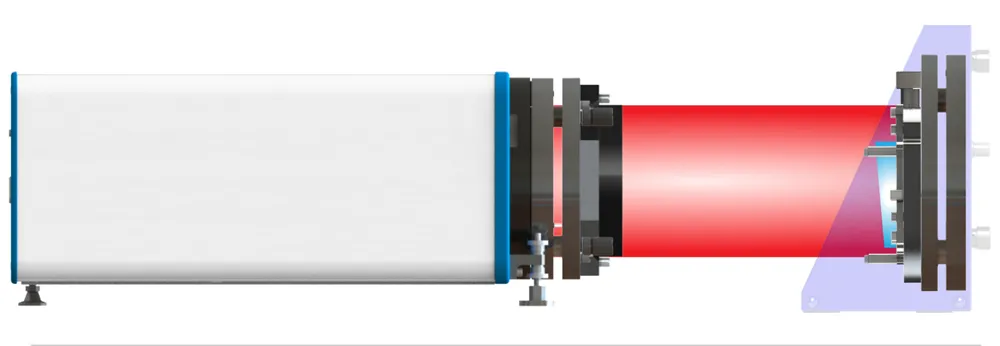

With the AccuFiz D short coherence Fizeau interferometer, an internal path matching system can be adjusted to produce fringes between any two parallel surfaces in the beam path (and excluding all other surfaces). In this way, the path match can be adjusted to only produce fringes between the front surface and the transmission flat, or the back surface and the transmission flat for a cavity up to 2 meters in length. Once the two surfaces are measured, the angle between them can be easily calculated.

Standard setup for measuring wedge and parallelism with a short coherence interferometer.

A “remote cavity” measurement can also be achieved by setting the path match to the optical thickness of the test optic. The front and back surfaces then become the test and reference surfaces, and no transmission optic is required to measure the angle between them.

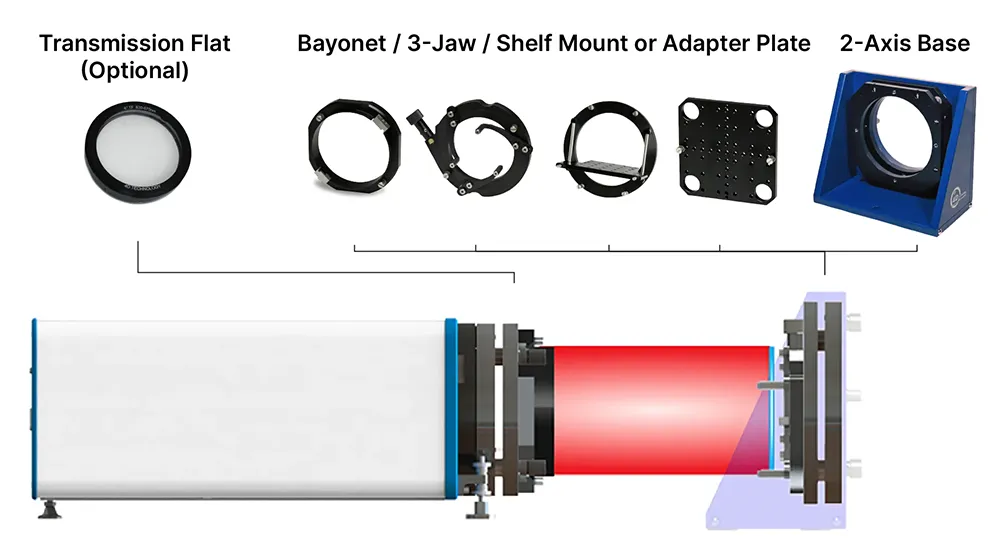

Required Equipment

| Required Components | |

| AccuFiz D Short Coherence Interferometer | More Information |

| Transmission Flat (not required for remote cavity measurement) | Specifications |

| 2-Axis Base with Tip/Tilt | Specifications |

| Bayonet, 3-Jaw or Shelf Mount, or Adapter Plate | Specifications |

Other Considerations

Measuring Larger Optics

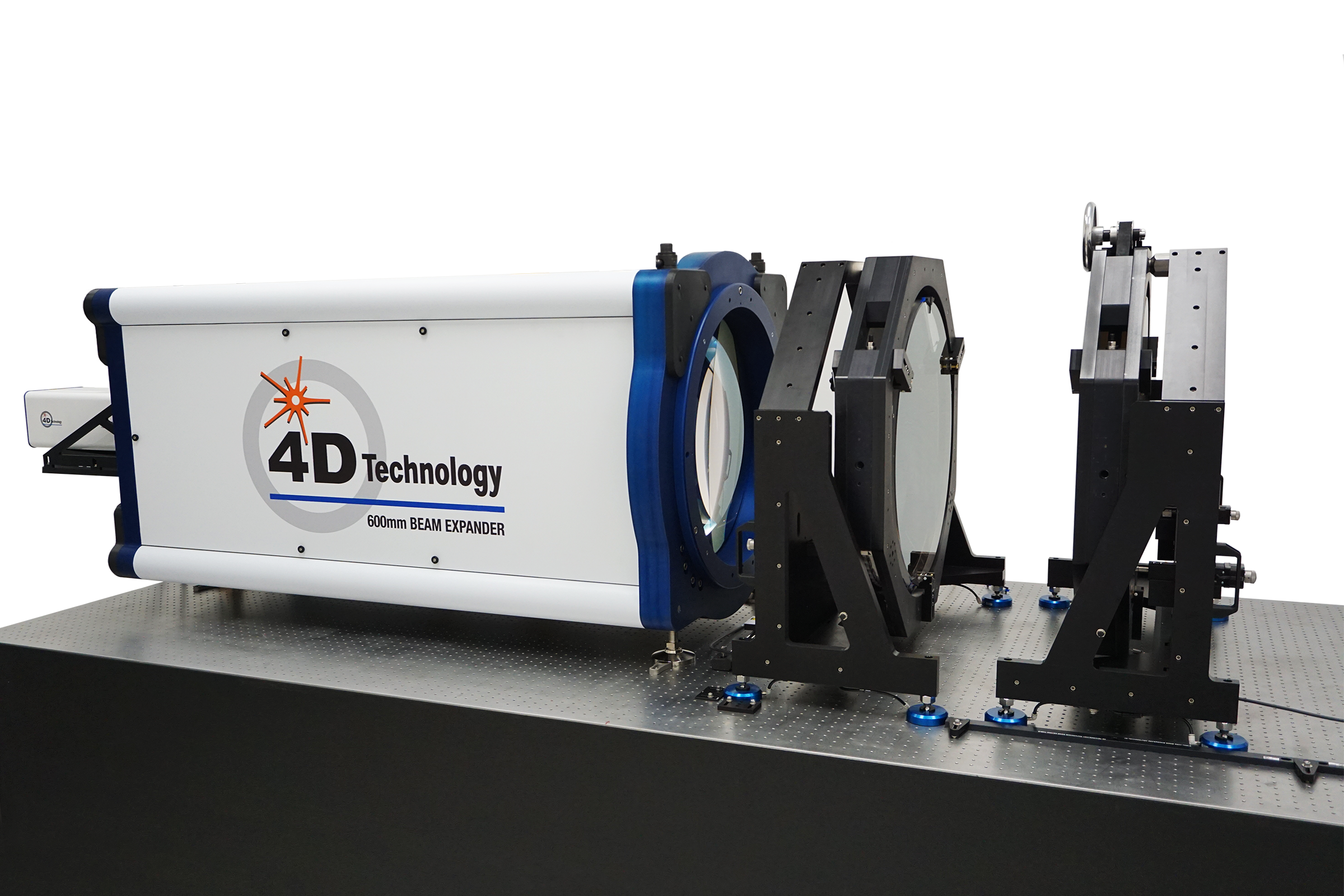

A beam expander enables measurement of flat optics larger than the instrument aperture. Beam expanders up to 600 mm are available for AccuFiz interferometers. The expanders include kinematic mounting which enables the instrument to be removed from the expander, used separately for smaller setups, then returned to the larger setup without realignment.

An AccuFiz D 100 mm aperture interferometer (left) used with a 600 mm beam expander and motorized, large optic mounts.

Measuring in Vibration

With a traditional, phase-shifting interferometer, measurement data is acquired sequentially—a long enough process that vibration and air turbulence will degrade or even prevent measurement. The interferometer and all mounts must be situated on an air table to isolate the system from vibration. Air isolation can be expensive—prohibitively expensive for very large optics or long measurement paths.

The on-axis AccuFiz D interferometer features Dynamic Interferometry®, which enables measurement data to be acquired simultaneously. Because acquisition speed is so fast, vibration is no longer an issue, and an isolation table is not needed.

ALTERNATE METHOD

Measure Using a Standard Fizeau Interferometer

A standard AccuFiz interferometer can be used with a Surface Isolation Source (SIS) to measure wedge and parallelism as well. The fiber-coupled SIS module lets you dial in any surface that is 88–112 mm from the aperture, as well as making solid cavity measurements of thin optics. Switch back to the primary source to use the AccuFiz to measure a broad range of other optical measurements.

Need Assistance with Measuring Wedge or Parallelism?

Contact our applications staff today for expert opinions on optical measurement and on measurement equipment.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed