Dynamic Interferometry

4D dynamic interferometers use patented, instantaneous phase sensors to measure the shape of surfaces with extreme accuracy, despite vibration and environmental noise.

The Limitations of Phase Shifting Interferometry

In the past, the largest limitation of phase-shifting interferometers (PSI) was their sensitivity to vibration and air turbulence. Traditional, temporal phase-shifting interferometers are particularly sensitive to vibration because the frames of interferometric data are acquired sequentially, over hundreds of milliseconds. The acquisition time is long enough that vibration and air turbulence cause unpredictable phase shifts between the data frames. The measurement accuracy is greatly reduced, and sometimes the environment is sufficiently bad that the measurement cannot be performed at all.

Dynamic Interferometers Measure Despite Vibration

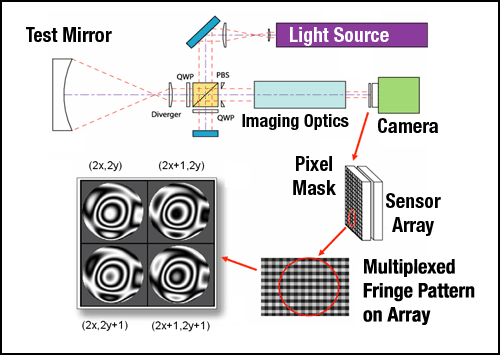

Dynamic Interferometry® makes it possible to acquire all measurement data simultaneously, with such short acquisition time that vibration and turbulence are effectively frozen. In 4D dynamic interferometers, a micropolarizer sensor array is used to spatially encode the captured interferometric image with four phase shifts of 0, 90, 180, and 270 degrees—enabling single frame, quantitative phase measurement.

4D Technology pioneered the use of Dynamic Interferometry and has been the major innovator in the field for nearly two decades.

4D holds multiple US and international patents on the technology and applications, including US Patents 6,304,330, 6552,808 and 7,230,717 (other patents pending).

Measure on the Shop Floor, in Cleanrooms

Because the exposure time is so short, the impact of vibration is effectively removed, enabling much improved accuracy even in noisy environments. In fact, a dynamic interferometer will give more accurate measurements if vibration is present and several data frames are averaged.

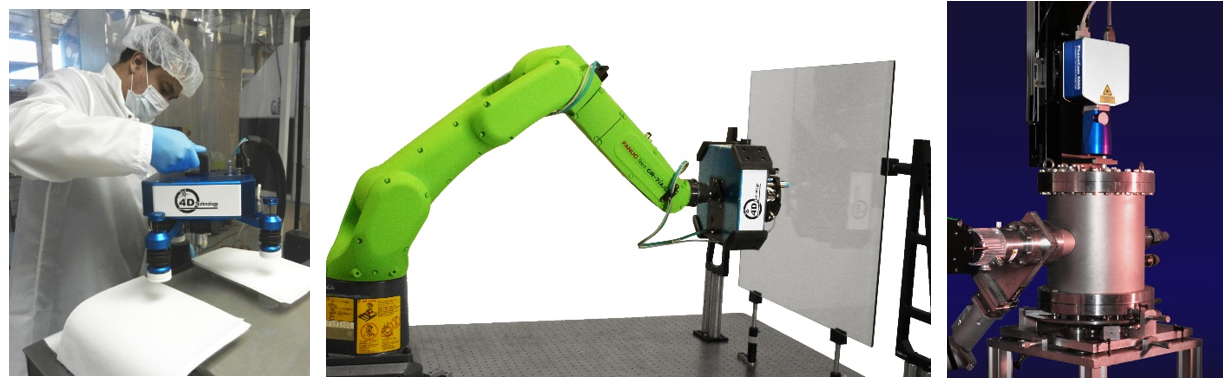

Dynamic interferometry enables measurements that have traditionally been difficult or impossible with temporal phase-shifting instruments. Dynamic systems can be used on the shop floor without air isolation tables, or in cleanrooms where noisy pumps and air handlers make traditional measurements extremely challenging.

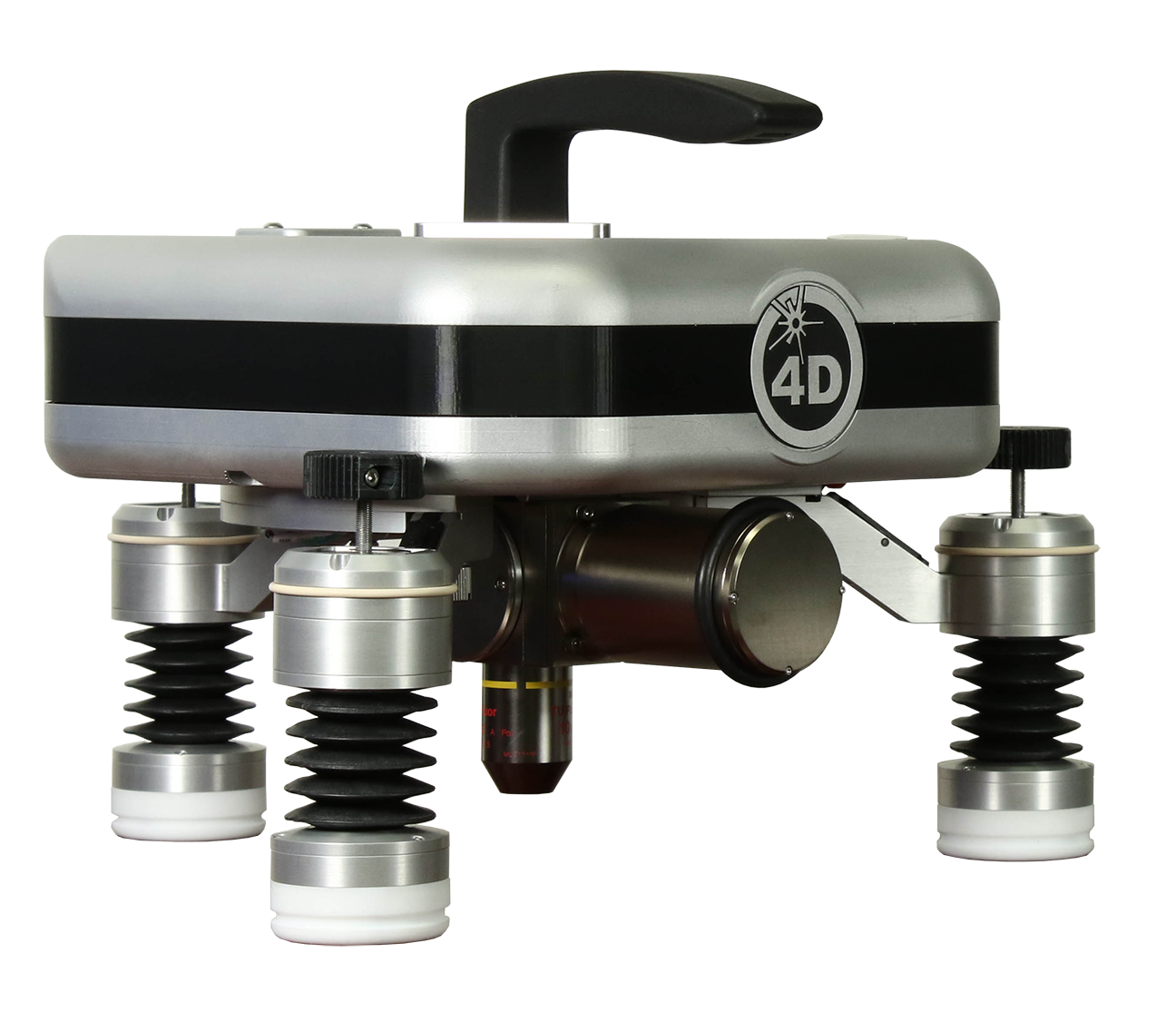

Handheld, Robotic, or Unisolated Mounting in Tight Spaces

Measurements can be made between multiple tables, through windows into environmental chambers, and over long stand-off distances. Odd shapes, pupil obscurations, poor signal contrast, moving parts, air turbulence and mechanical vibration are not problems.

Measure Moving Systems

Dynamic interferometers have been developed for use at a wide variety of wavelengths. Other systems feature high spatial resolution to measure steep slopes, high powered sources for low-return setups, and very small form factors for handheld use or mounting in-line for production measurements.

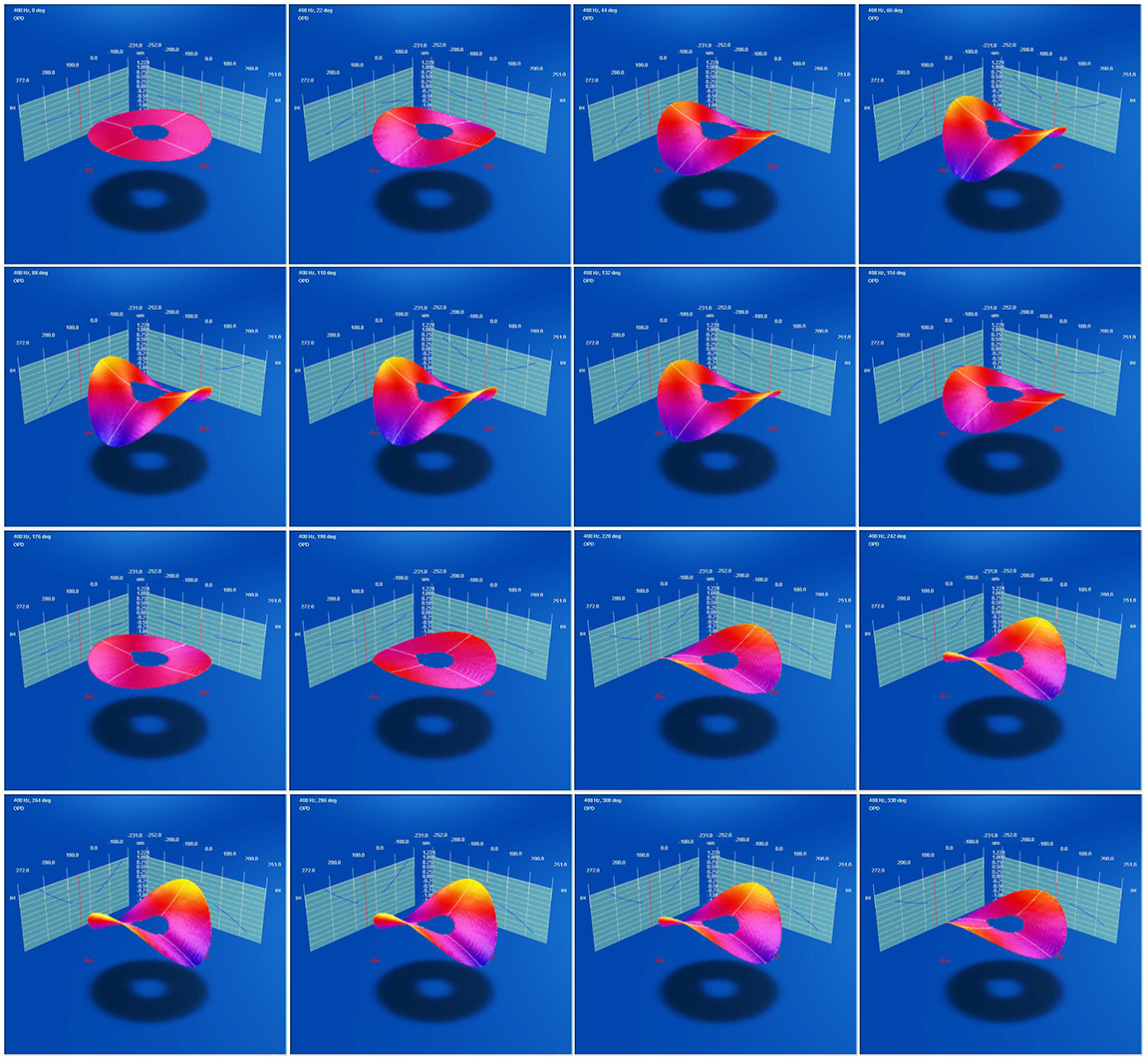

The extremely short exposure time also enables a dynamic interferometer to analyze moving or vibrating systems. The vibration modes of spinning disks, actuating micro-devices, thin mirrors and many other systems can be accurately assessed over time.

4D Dynamic Interferometers

Twyman-Green Interferometers

Excels at fast, repeatable measurement of surface shape and transmitted wavefront error of concave, flat and convex optics.

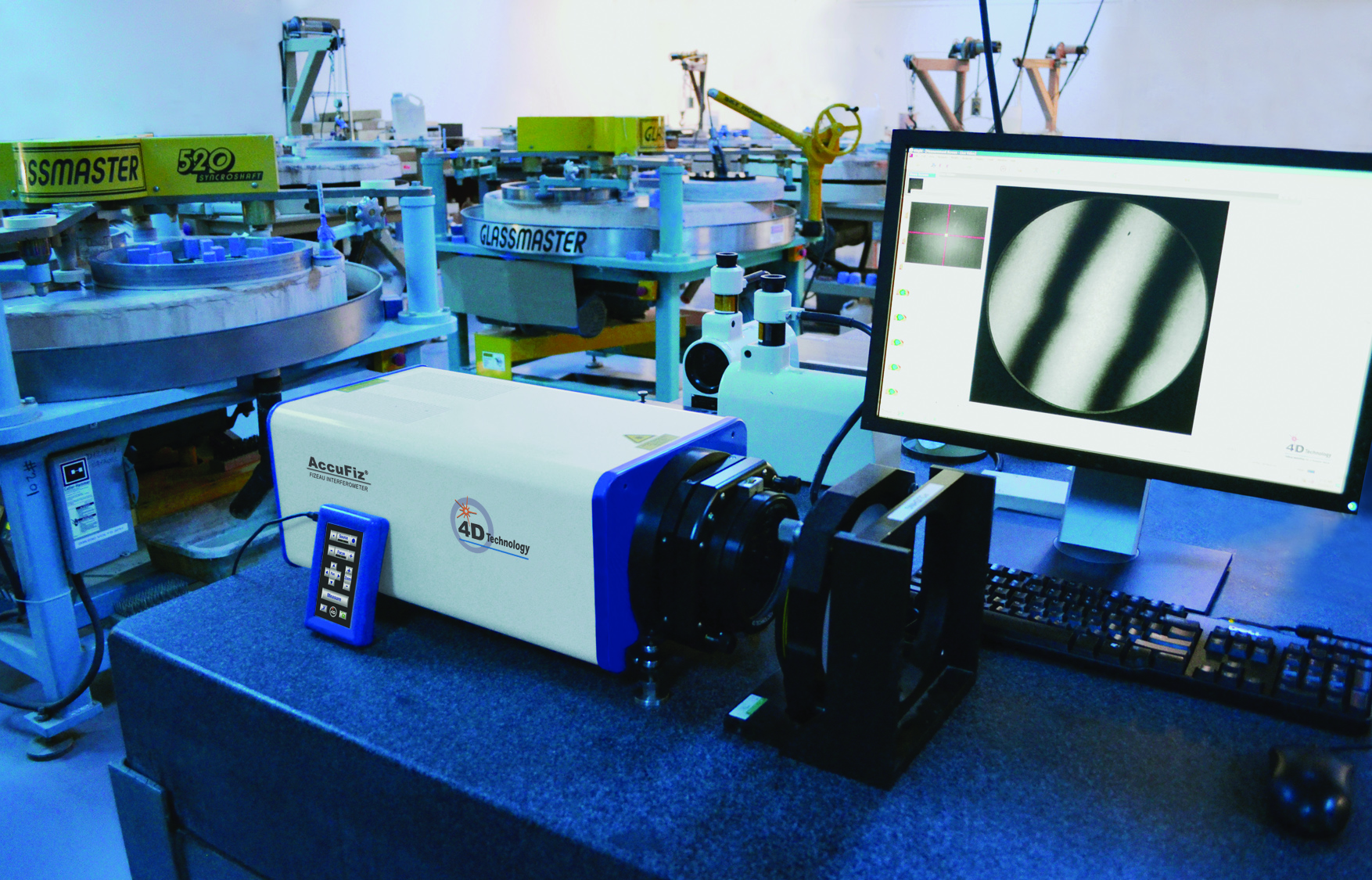

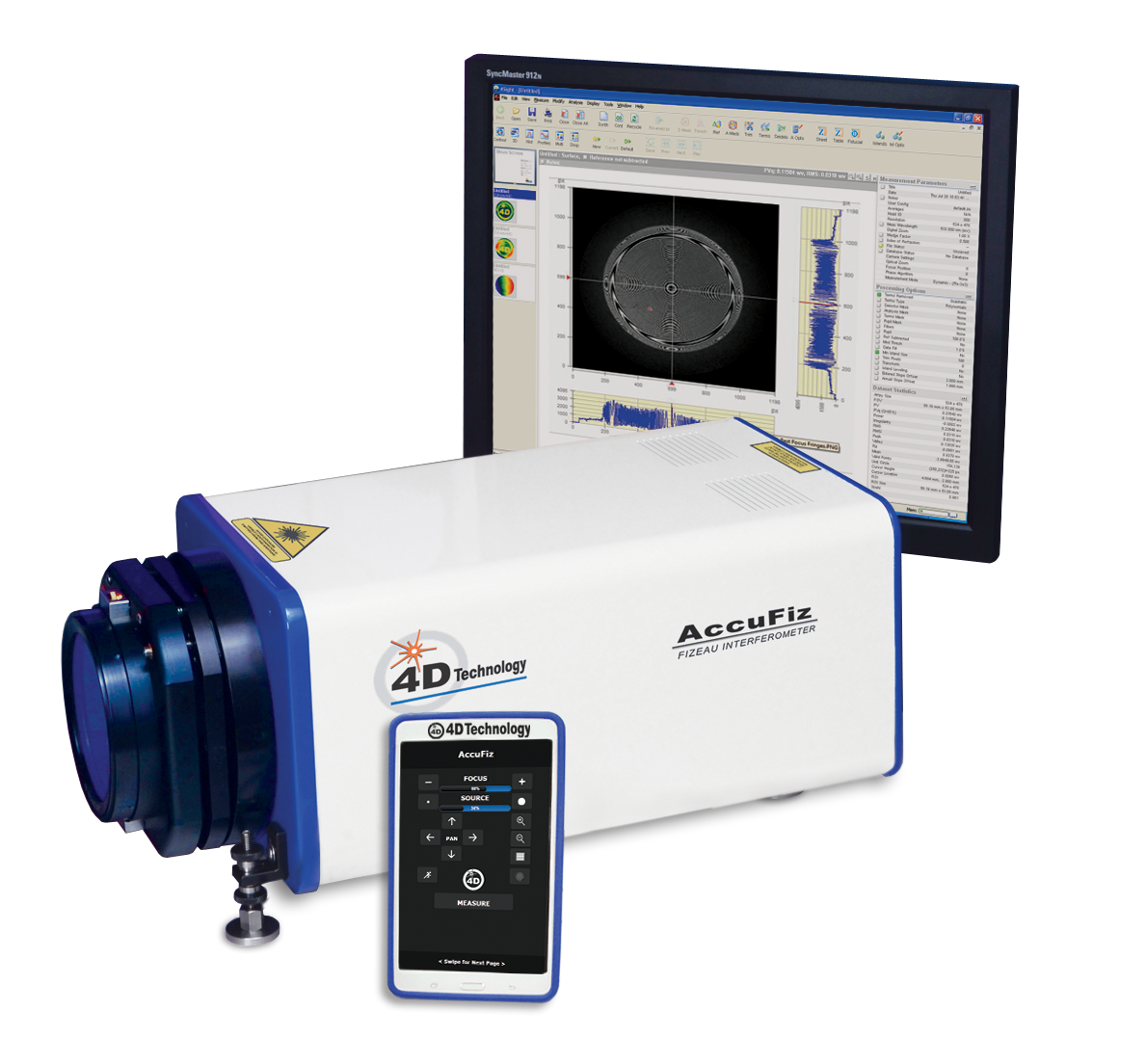

Fizeau Interferometers

Measure flat and focal optics, including measuring both sides of transparent, parallel optics as thin as 200 microns. Measure surfaces in multi-surface optical systems, remote cavity test setups, and solid cavities such as etalons (laser rods).

Dynamic Optical Profilers

NanoCam measures surface roughness on coated and uncoated surfaces to ensure the quality of polishing processes.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed