Accessories and Options

Increase productivity and ease of use with the 4D InSpec surface gauges.

Portability, convenience, and ways to make difficult measurements.

4D InSpec Options and Accessories

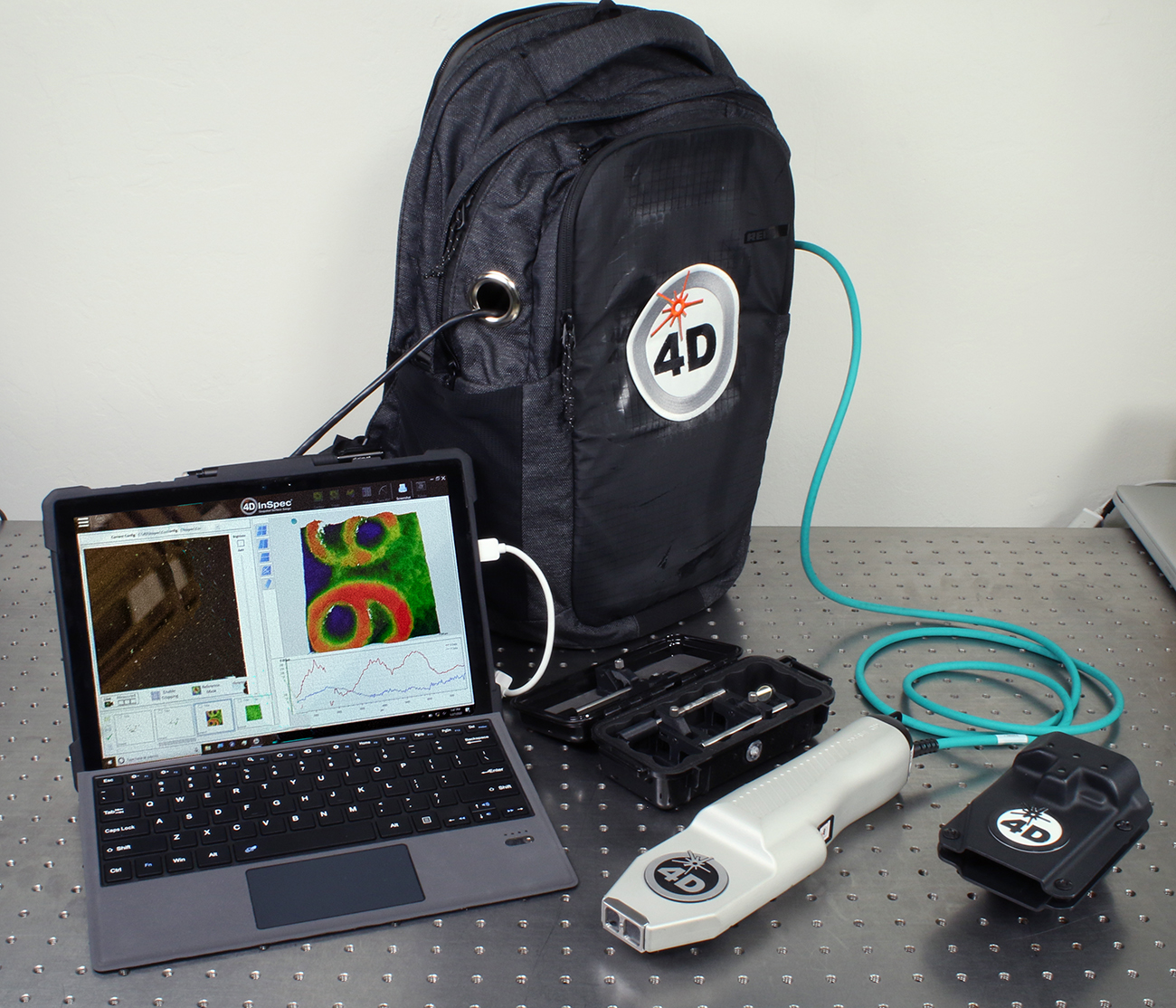

Backpack Kit

The 4D InSpec backpack kit brings precise, 3D surface measurement wherever it’s needed. Measure large components anywhere on the factory floor. Inspect rivets on an airplane wing, a helicopter on the deck of a ship, or the flanges of wind turbines.

To measure, just:

• Pull the gage from the holster

• View the screen on the tablet computer to focus

• Click the button to see and save results in seconds.

Weighing less than 15 lbs (7 kg), the backpack kit is comfortable for extended use, even in challenging measurement locations. An optional battery enables extended operation.

The 4D InSpec backpack kit includes:

- lightweight and durable backpack

- belt-mounted holster

- ruggedized tablet computer (Microsoft® Surface Pro 6 or

equivalent) and Windows® 10 or higher - USB-to-Ethernet adapter cable

- neoprene pouch to protect the gage

- case for focus aids and fold mirrors (sold separately).

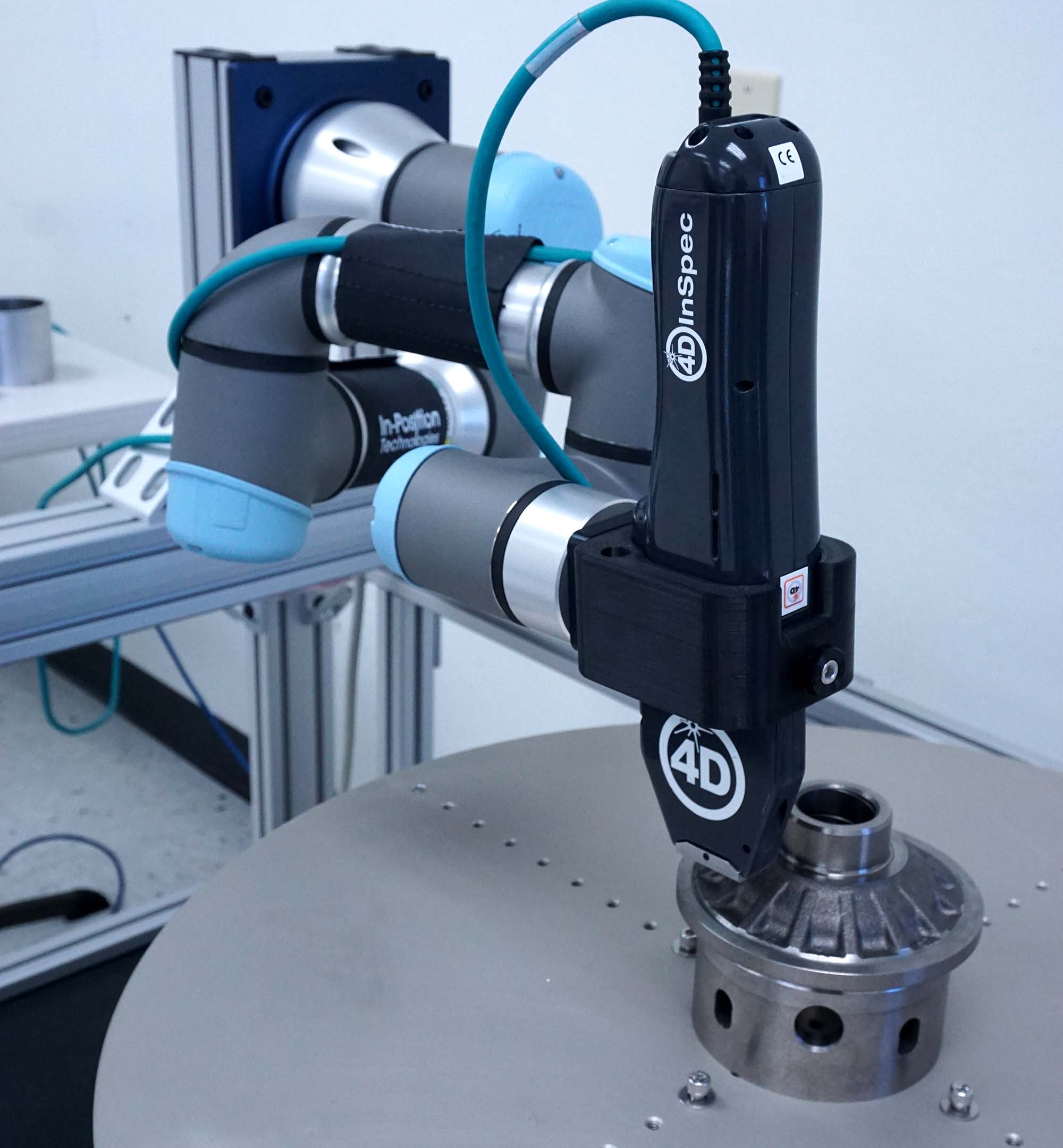

Robotic Automation

Improve measurement repeatability by adding robotic automation to the 4D InSpec (or XL). The UR Robot is natively integrated into the analysis software, so you can be operating and training your robot in minutes. The built-in API helps you edit connections to other robots, rotary tables and rotary stages quickly.

Portable cart

The portable cart provides a means of taking your inspection gauge around the shop floor, as shown on the left.

The portable cart holds the all-in-one computer on a swivel arm, as well as the 4D InSpec and its stand on the adjustable shelf.

Adjust the height: Raise the monitor and shelf for standing use, or lower the monitor when measuring a part that is sitting on the floor. The articulated arm is easily positioned for use in tight quarters and to reduce glare in factory lighting conditions. The cart can also securely hold the 500W power supply accessory.

Flexible Mounting Arm

The Flexible Mounting Arm attaches to the main post of the workstation stand, which is included with the 4D InSpec. The 560 mm (22 in) long arm lets you position the 4D InSpec at any orientation within approx. 150 mm (12 in) of the vertical post. It includes a fine focus adjustment to help you obtain and hold good focus and signal strength for any surface, with no part fixturing required.

Fold Mirror Kit

Perfect for measuring larger bores or difficult to reach sidewalls, fold mirrors are used instead of the standard alignment aid to measure difficult-to-access areas, such as the sides of pipes, the surface between turbine blades, the area under a lip or flange, etc. The kit includes four mirrors:

- 20 mm left-hand fold

- 20 mm right-hand fold

- 12 mm left-hand fold

- 12 mm right-hand fold.

All fold mirrors are mounted at 45 degrees to bend the test beam 90 degrees. The standoff distance is set for full compatibility with the 4D InSpec. A hard shell carrying case is included.

Small Bore Mirror

This fold mirror lets you inspect deep into 3/4 in or larger diameter holes.

4D can also design and manufacture custom alignment fixtures, fold mirrors and measurement aids to meet the requirements of your particular application.

500W Portable Uninterruptable Power Supply (UPS)

This battery power supply runs the 4D InSpec and computer for approximately 8 hours of standard use, or 6 hours of high-intensity use, without a need to plug into a wall outlet. The power supply provides improved portability for use throughout the shop floor. The power supply securely mounts to the LCD cart and detaches with a single thumbscrew. It can be carried in a backpack for walking portability kits.

Buy multiple power supplies, so that one can be charging while the other is in use, allowing outlet-free operation of the 4D InSpec over multiple shifts.

Calibration Standard with Height Certification

This 4D Technology -designed depth standard enables vertical calibration and verification of the 4D InSpec Surface Gauge. The standard includes grooves from 1 µm to 900 µm deep. 4D uses the 100, 200, 600 and 900 µm grooves for 4D InSpec calibration. Each standard comes complete with a storage box as shown.

The standard is made from pure copper (OFHC-Cu) which provides the best surface qualities (arithmetical mean deviation Ra = 1 nm, waviness Wt = 50 nm, flatness 50 nm over 20 mm measurement length). The copper disks are 90 mm in diameter and 10 mm thick. After machining the disc with rotationally symmetrical grooves, wire EDM is used to cut the disk into twelve segments of equal size which are then chemically nickel-plated to a thickness of 5 µm. The surface hardness of the standards is then about 500 HV and wear-resistant.

The four grooves used for 4D InSpec calibration are ISO-certified using high-resolution metrology, providing greater accuracy for 4D InSpec calibration. This standard is recommended for QC departments that require the highest accuracy standards. The uncertainty of the grooves will be:

- 100 µm groove: 80 nm

- 200 µm groove: 100 nm

- 600 µm groove: 100 nm

- 900 µm groove: 180 nm

Lateral Calibration Standard

The lateral calibration standard used for the 4D InSpec is a 1.000” diameter Steel pin gauge with Black Guard coating. The pin gauge is class ZZ, with a tolerance of ± 0.0002 in (0.005 mm). The Radius of Curvature calculation can be used in the InSpec software can be used to verify the lateral calibration of the InSpec, which when properly calibrated will give the radius of this gauge as 0.5 in. The pin gauge has a 10 microinch (25 nm) finish, is 2 in long, and comes with a certificate of accuracy.

USB Foot Pedal

4D InSpec measurements can always be initiated using either the trigger button on the measurement head or the software controls on the touchscreen.

The USB foot pedal provides a third, hands-free option to initiate a measurement when measuring difficult geometries or large parts. All three methods are available at all times, providing maximum flexibility to easily achieve good surface defect measurements.

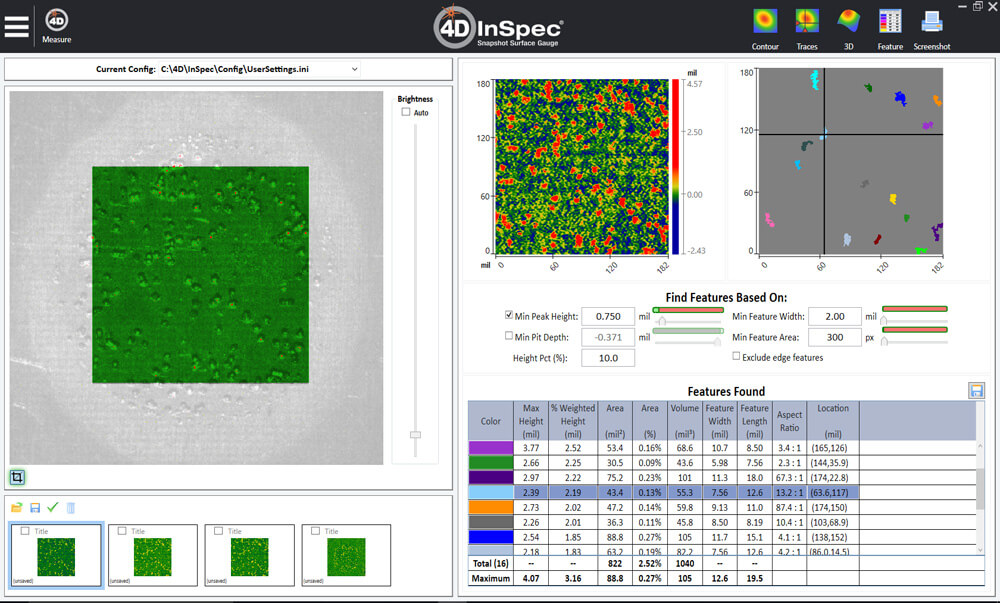

Stand-Alone Software License

This option lets you install an additional copy of the 4D Inspec software on a computer which is not connected to the 4D InSpec instrument. The extra copy makes it possible to load, analyze and modify measurements from the instrument at the convenience of a separate Windows® 10-based computer, while the instrument continues to be used.

Remote Access Software

This option enables Windows Communication Foundation (WCF) functionality with the 4D InSpec software such that the Surface Gauge may be controlled remotely via a user-written application. This functionality makes it possible, for example, to integrate the 4D InSpec into an automated platform. With the remote access software package you can trigger such actions as grabbing a live camera image, opening a configuration file, taking a measurement, performing the Feature Analysis calculations, or other key operations that normally happen via the 4D InSpec’s own graphical user interface.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed