Painted Surfaces

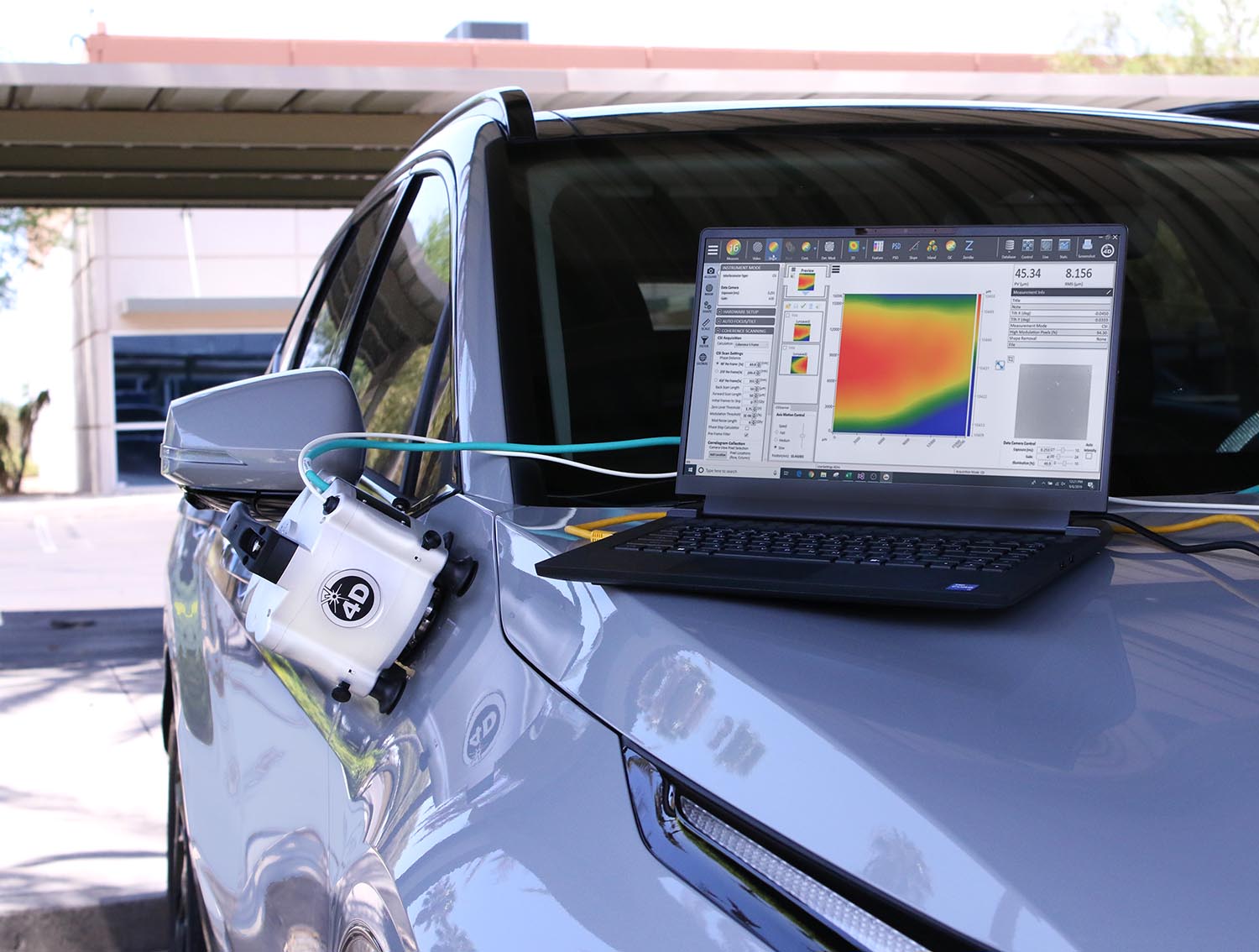

The 4D SurfSpec is the first surface measurement system for process control of coatings from substrate to clearcoat. Comprehensive, quantified results let you fingerprint the entire process—to ensure final coating quality, and to prevent further processing on parts which will lead to unacceptable final quality.

The portable 4D SurfSpec can be used either handheld or robot-mounted. Test any of the common locations-of-concern on a body-in-white, then retest the same locations after coating to trace results throughout the process. The 4D SurfSpec measures in any orientation, even upside-down, on verticals, and on curved surfaces.

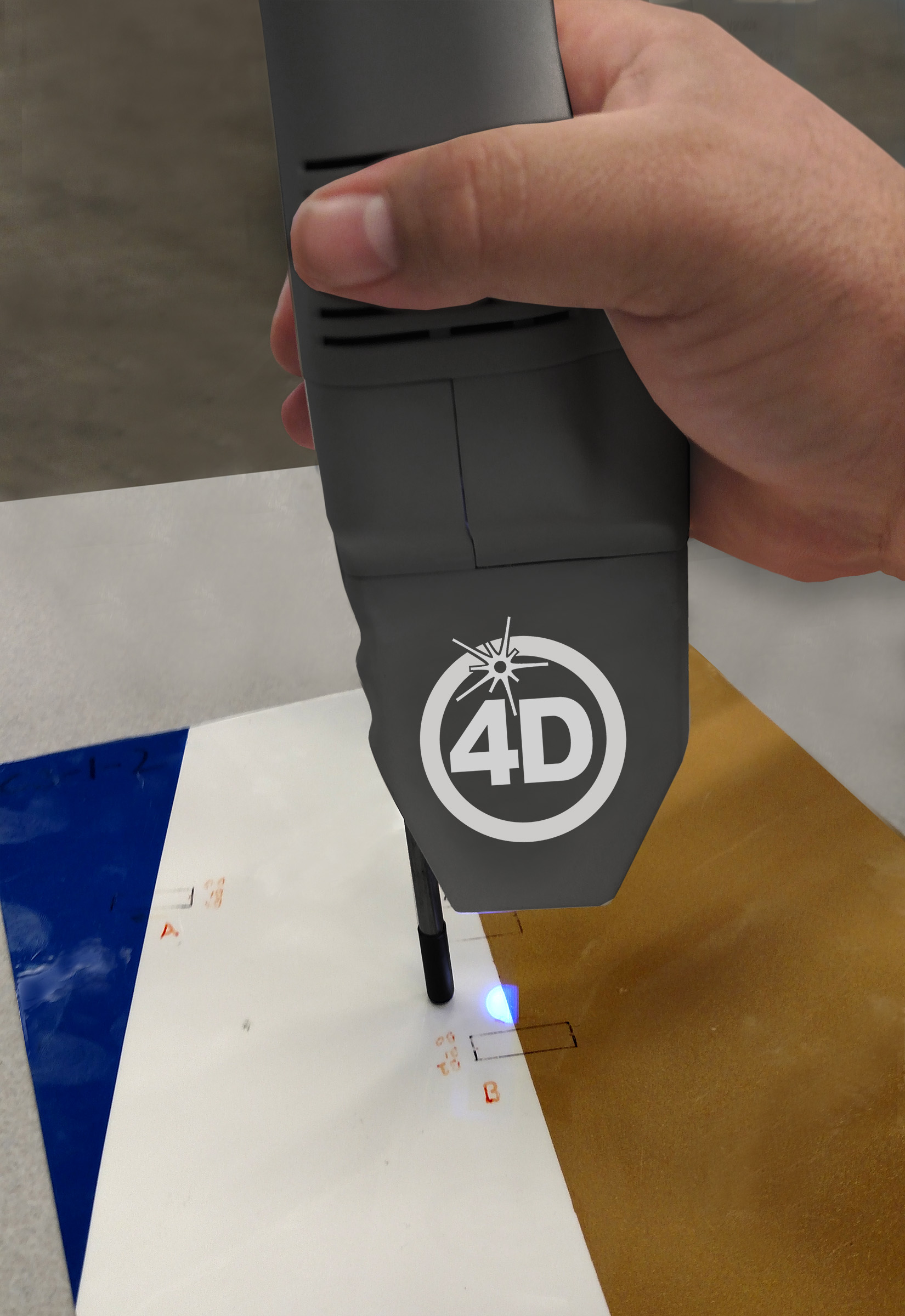

Gloss or matte, 4D InSpec measures painted surfaces, and defects in painted surfaces.

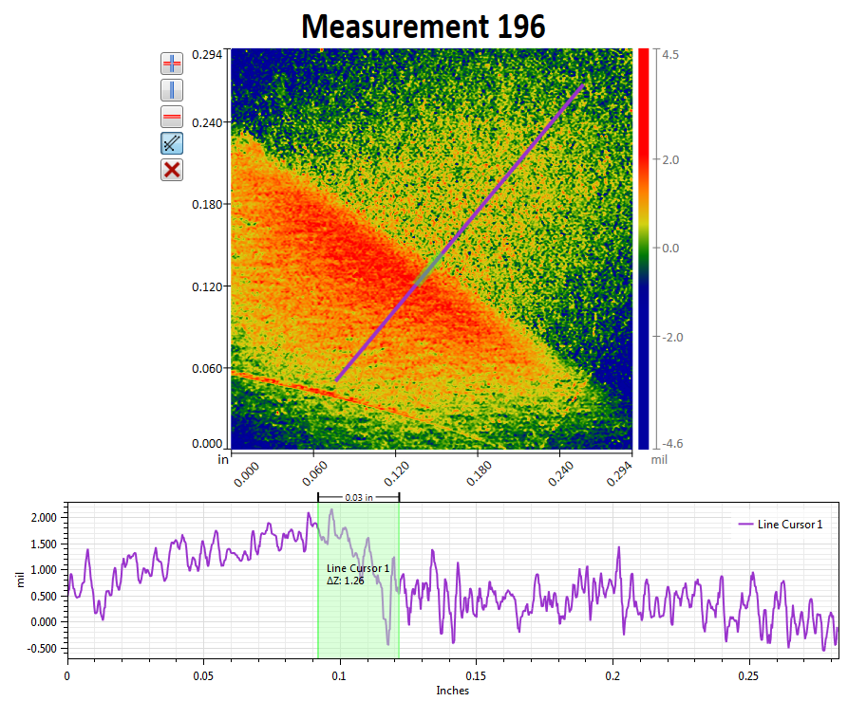

On the painted sample above, we measured the step represented by the edge of the painted area. 4D InSpec readily measures the two different colored materials. The gloss finish of the paint and adjacent unpainted surfaces also are not a problem.

Notice that, because of the 3D area captured, it is not a laborious task to line up the instrument perpendicular to the step to get an accurate measurement. It’s much easier to find a perpendicular on the measurement plot, because of enlargement and the versatility of the profile line tool.

Reviewing the data (below), you can draw a profile across the transition area. Using area reference masking to average the height of the paint plateau, or more commonly the flatter unpainted lower area, the step becomes clearer and numerically quantifiable.

Added Technical Resources

Measuring Automotive Paint from Substrate to Clearcoat

Read how measuring each step lets you correlate the surface roughness at every step to final coating quality.

Measuring Transparent or Shiny Surfaces with 4D InSpec

Learn why transparent and shiny surfaces present a special challenge, and how to make good measurements with 4D InSpec.

Learn more about the products

4D InSpec

4D InSpec provides non-contact measurement of surface features and defects, on the factory floor, in machine shops and in field service applications.

4D InSpec XL

A handheld defect inspection gauge that works like 4D InSpec standard, but with a larger field of view, to measure wider and deeper features.

InSpec Accessories

Accessories for improving portability, ease of use, or for accessing hard to reach measurements like sidewalls and through-holes.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed