Surface defect gauge measures larger features

4D InSpec® XL Surface Defect Gauge.

The 4D InSpec XL Surface Defect Gauge expands 4D Technology’s 4D InSpec product line—they’re the first handheld, precision instruments for 3D non-contact surface defect measurement.

Handheld 3D surface defect gauge

The 4D InSpec XL has a larger field of view and higher scan range than 4D InSpec. The features you measure can be up to 0.6″ x 0.6″ across. You still get micrometer-level resolution, portability, affordability and ease-of-use. It measures and reports in under a second. 4D InSpec XL puts high resolution metrology on the factory floor, in machine shops, on the flight-line, and in field-service’s hands. So you don’t have to wait for the metrology lab’s report.

4D InSpec XL quantifies defects such as pits, scratches, nicks, dents and bumps, and measures features such as edge break, radii, rivet depth and dot peen depth, from 0.0002″ (5 microns) to 0.35″ (9 mm) deep/tall. 4D InSpec is far more repeatable and accurate than visual comparison techniques typically used for surface defect measurements.

And unlike high-end metrology systems it is rugged, flexible and affordable, to measure a wide range of part geometries in the most challenging environments.

“Our three 4D InSpecs paid for themselves in a week.”

So easy, you can learn to use it in 10 minutes

No replicas, less dismantling of big parts. Just place it and click:

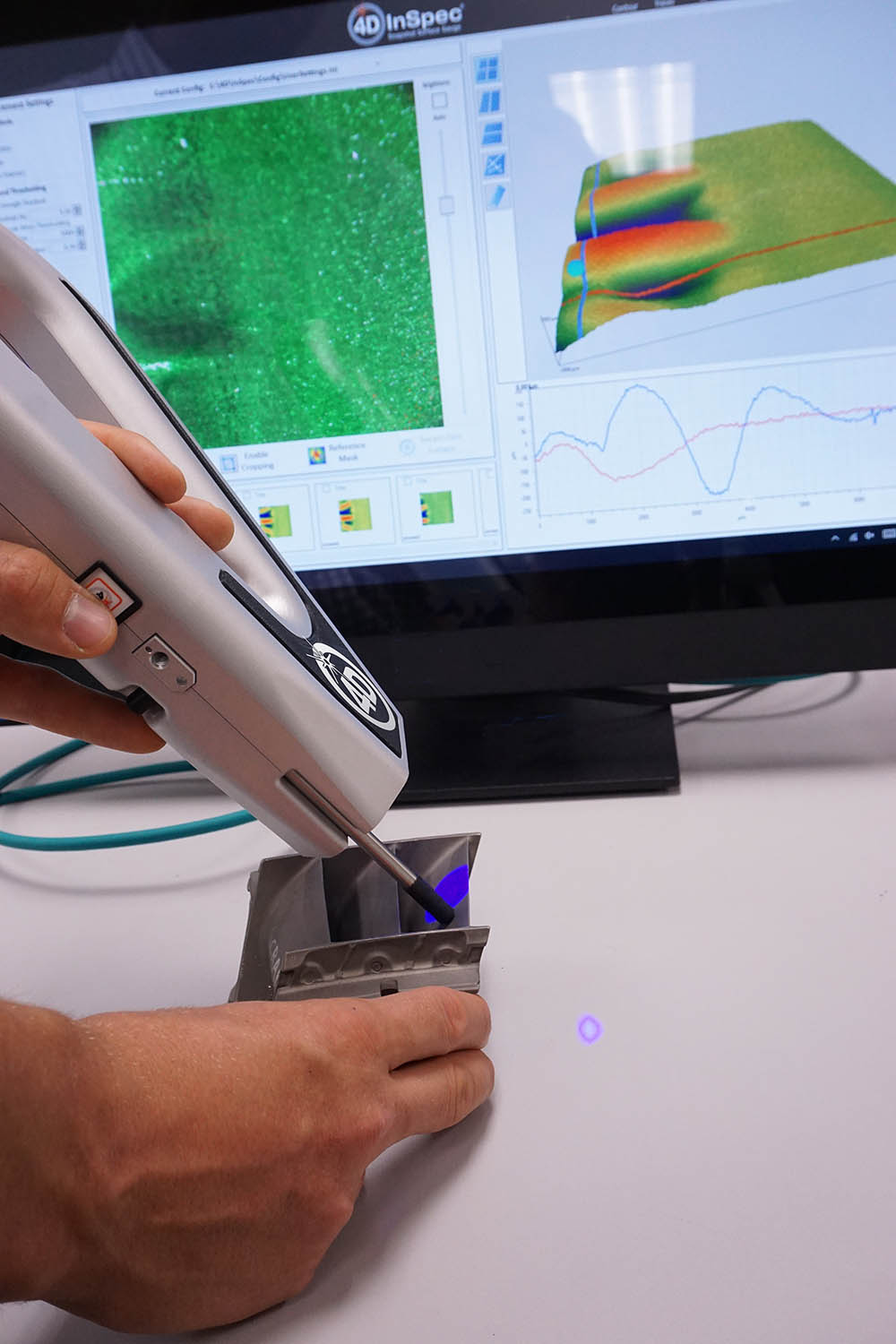

- Touch the standoff leg to the part: you’re in focus

- Tilt the surface defect gauge until the preview turns bright green: you’re perpendicular to the surface

- Press the button on the gauge: your measurement appears on the screen in about a second

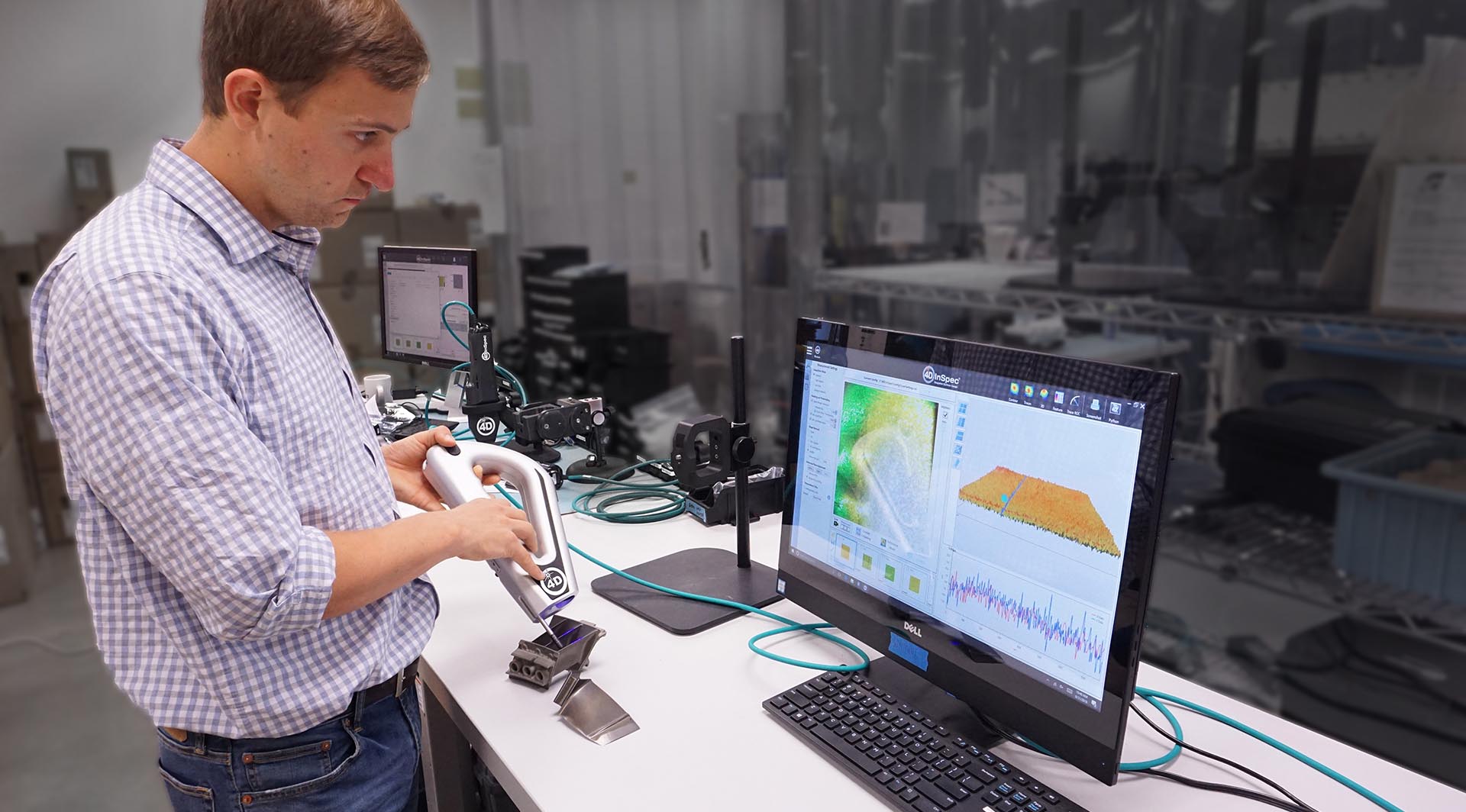

Hold the 4D InSpec in your hand to access tight corners or to sample large surfaces directly on components. One-button operation and immunity to sensor movement make it easy to align and measure, while a rugged design and single cable tether withstand the rigors of daily use. So you never need to wait for a replica to set up.

Workstation setup

In a workstation configuration, 4D InSpec XL makes it fast and easy to obtain repetitious and repeatable quality control data. A touchscreen interface handles setup, operation, analysis and report generation. A holding stand keeps the gauge in the same place, so you can slide similar parts into and out of position. Watch the preview on the screen to locate your defect under the gauge. Touch the button on the screen or on the gauge—or use the mouse—to take a measurement.

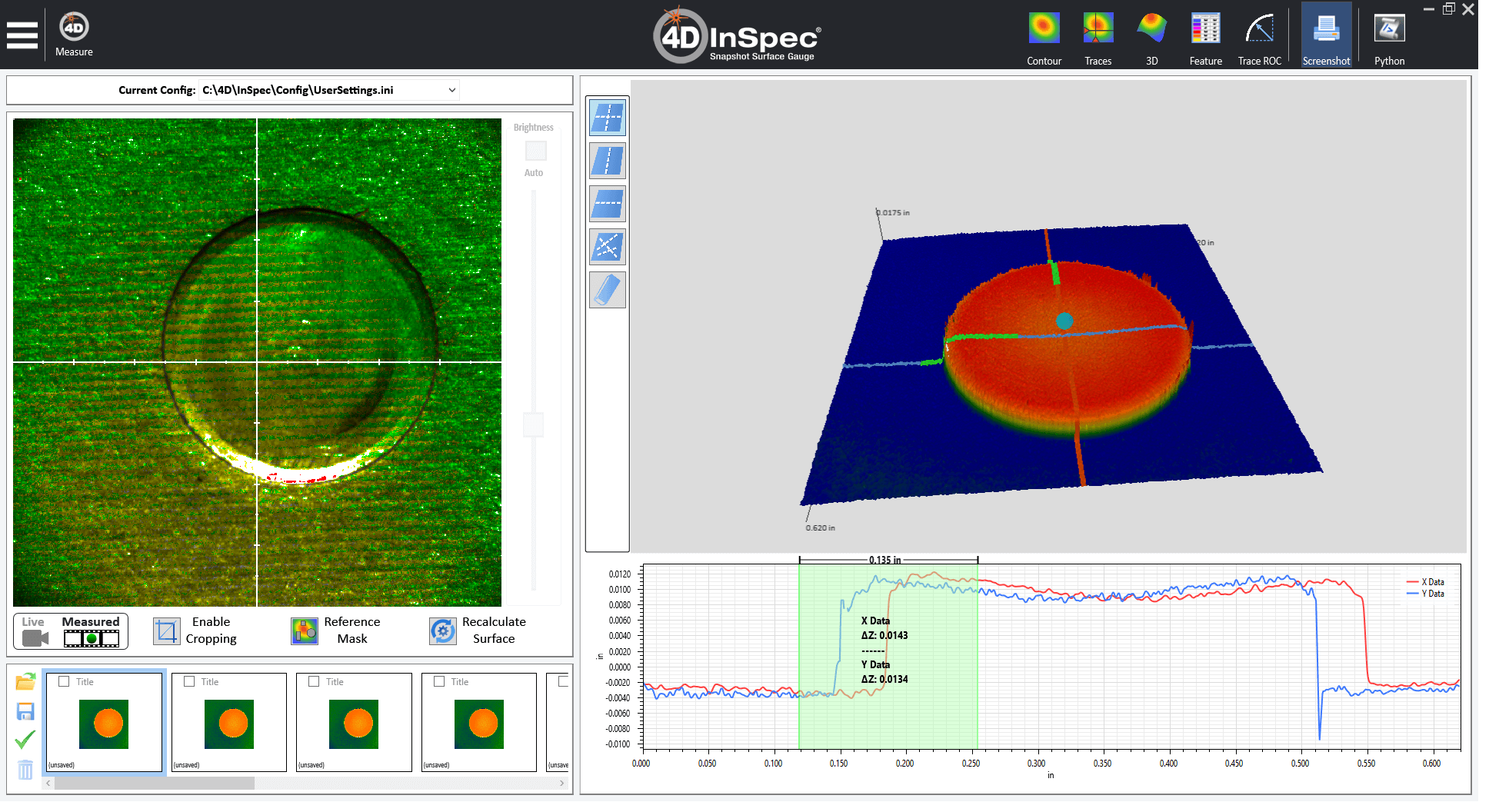

The included software with intuitive touch-screen interface automatically locates defects and calculates their height, volume, area, slopes and location. The operator can choose from 2D traces or 3D plots to view defects in great detail. Calculate radius of curvature of grooves, rods and spheres. The gauge also supports easy data transfer to quality control systems via LAN, USB or WiFi for rapid pass-fail analysis.

Learn about the 4Di InSpec AT

for automated feature and defect measurement

What to expect

4D InSpec XL is an optical gauge using projected structured light to measure surfaces in 3D with microscopic resolution.

Using super-fast dynamic measurement techniques, the instrument is immune to vibration and tolerant of motion, so it can be used hand-held, or mounted on a robot arm in a noisy, vibrating production environment.

| 4D InSpec XL | Spec |

| Field of view | 0.6″ x 0.6″ (15mm x 15mm) |

| Depth of Field | Resolves defects from 0.0003″ to 0.35″ high or deep |

| Vertical Resolution | Better than 0.0003 inches |

| Lateral Resolution | Less than 10 microns |

A complete 4D InSpec system includes:

- The instrument gauge

- Computer with HD 1080p touch-screen interface

- Single Ethernet cable tether

- Measurement and analysis software

- Benchtop stand for setting focus and placing parts for repetitive measurements

4D InSpec mounts on robotic manipulators as well, for fully automated measurements of complex components.

4D InSpec analysis software, included with every 4D InSpec, features excellent ease of use and a short learning curve.

Automatic feature finding detects outliers of height, depth, area or count for instant pass/fail qualification. In Feature mode, create as many bins and parameters to review in the measurement as you need to be sure the geometry is certain.

2D and 3D displays, filtering, thresholds and masking tools make it easy to highlight and quantify surface shape and texture. Analysis tools like X,Y or arbitrary traces help you corrolate results to linear measurements.

Comprehensive data sharing capabilities let you read, write, save and print data in many common file formats for data retention and reporting.

Visit the Analysis Software page to see screen captures and features demonstrated.

4D InSpec XL offers a full set of accessories to improve portability and productivity, including:

- A portable wheeled workstation, with touch screen computer and Li-ion rechargeable battery with up to 8 hours operational time

- Flexible arms for positioning the 4D InSpec at any angle and holding it

- Foot pedals, for taking a measurement when your hands are full

- Calibration standards

- Remote workstations for reviewing data

- Offline analysis licenses

Visit the Accessories page to get details and see pictures.

Feature

analysis software

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed